2026 Best Car Brake Parts for Safety and Performance Insights?

In the world of automotive safety, the role of car brake parts cannot be overstated. Experts in the industry stress their importance. John Peterson, a noted automotive engineer, asserts, “Quality brake components save lives.” His insights highlight the need for reliable and high-performing brake parts.

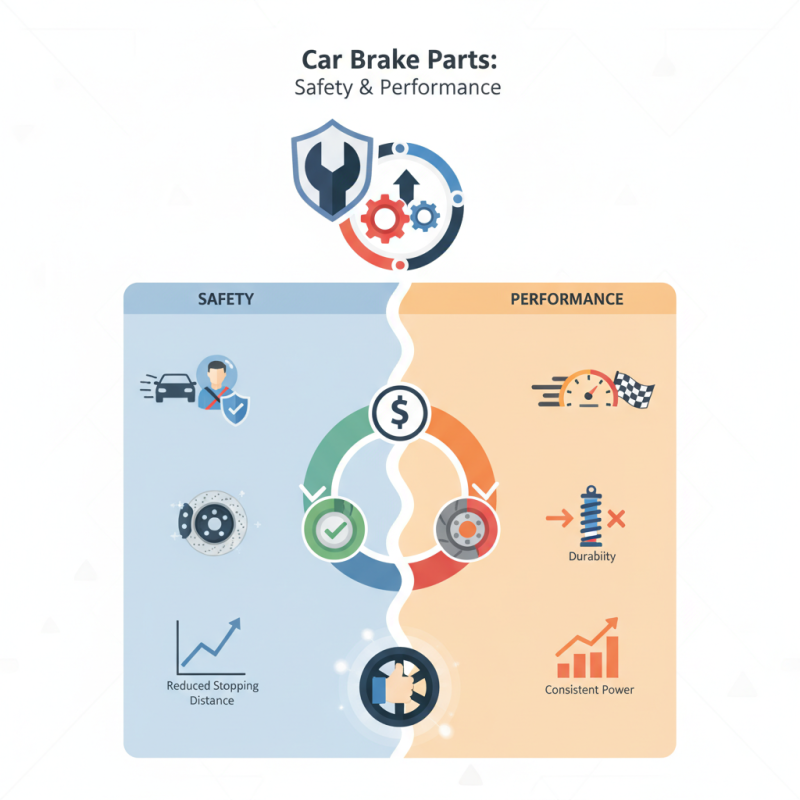

Choosing the best car brake parts is vital for both safety and performance. Drivers should seek parts that provide consistent stopping power and durability. However, selecting the right components can be overwhelming, given the myriad of options available. Many don't realize that inferior parts can compromise vehicle safety.

It’s essential to reflect on the impact of our choices. Investing in high-quality car brake parts pays dividends in the long run. Often, the temptation of cheaper alternatives can lead to serious consequences. Understanding this helps drivers make informed decisions.

2026 Trends in Car Brake Parts: Enhanced Safety Features and Technologies

As we move into 2026, advancements in car brake technology are noteworthy. Enhanced safety features are becoming essential. Systems with improved anti-lock braking mechanisms help drivers maintain control in challenging conditions, like rain or snow. These technologies minimize stopping distances, which can be critical in emergencies.

New materials, such as carbon ceramic composites, will gain traction. They offer better heat resistance and less brake fade. However, some drivers may find these materials can be noisy and require adjustment. This transition highlights a need for better education on how to handle modern brake systems, as not all drivers are familiar with their unique idiosyncrasies.

Moreover, electronic brake systems are emerging. They provide responsive feedback and adaptive braking, yet some consumers hesitate due to reliability concerns. There is an ongoing debate about the balance between advanced features and driver comfort. These evolving trends invite reflection on how drivers engage with their vehicles on various levels, reshaping the braking experience.

2026 Trends in Car Brake Parts: Enhanced Safety Features and Technologies

This chart illustrates the advancements in car brake parts over the years 2024 to 2026. It showcases the percentage of various safety features adopted in new brake systems, highlighting the growing importance of technology in automotive safety.

Key Performance Metrics for Evaluating Brake System Components in 2026

In 2026, evaluating brake system components requires keen attention to key performance metrics. Factors such as stopping distance, fade resistance, and pedal feel play a significant role. A recent industry report highlights that 60% of accidents can be traced back to brake failures. Understanding these metrics is essential for enhancing vehicle safety.

Stopping distance is critical in assessing brake efficiency. Ideal performance requires a stopping distance of less than 120 feet from 60 mph under standard conditions. Unfortunately, not all components meet this benchmark. Some systems struggle with heat accumulation, leading to brake fade. It’s crucial to analyze materials used in brake pads and rotors, as they directly impact thermal management.

Tip: Regular testing of brake performance can reveal early signs of wear. Drivers should monitor pedal feel. A spongy pedal could indicate hydraulic issues.

Furthermore, evaluating noise and vibration levels can provide insight into performance consistency. Unusual sounds from brakes can indicate problems that deserve attention. Compromised safety can stem from ignoring these signs. Knowledge of performance metrics helps drivers make informed decisions about brake maintenance.

Tip: Don't wait for warning lights. Schedule regular inspections to ensure safety and optimal performance.

Innovative Materials in Brake Parts: Reducing Weight without Compromising Safety

In recent years, the automotive industry has seen a shift towards innovative materials in brake part manufacturing. By utilizing advanced composites and lightweight alloys, manufacturers aim to enhance performance while maintaining safety standards. According to a report from the Society of Automotive Engineers (SAE), the integration of such materials can reduce brake system weight by up to 30%. This reduction plays a crucial role in improving vehicle handling and fuel efficiency.

However, reducing weight is not without its challenges. Striking the right balance between performance and safety is essential. Lighter materials can sometimes lead to concerns regarding heat dissipation and wear resistance. For instance, while carbon-ceramic brakes offer reduced weight and enhanced stopping power, they can exhibit varying performance in extreme conditions. About 15% of drivers report discomfort feeling their vehicle's response in emergencies, highlighting the need for ongoing research.

The industry's push for lightweight brake components reflects broader trends towards sustainability. Engineers are tasked with developing solutions that not only minimize weight but also maintain reliability. The goal is clear: enhance vehicle safety without compromising performance. Continuous innovation is key. Yet, as seen in practice, there is always room for improvement. Feedback from users is invaluable. The road ahead demands diligence and collaboration to address these critical concerns.

The Impact of Regular Maintenance on Brake Performance and Longevity

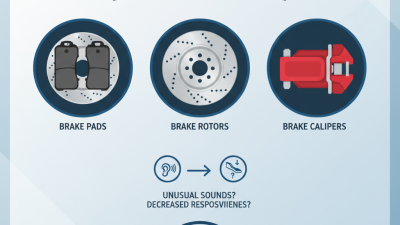

Regular maintenance plays a crucial role in enhancing brake performance and longevity. Neglecting this aspect can lead to serious safety issues. Regular checks allow for the early detection of problems, such as worn-out pads or fluid leaks. Without these checks, minor issues can escalate, resulting in costly repairs and potential accidents.

Brake components experience wear and tear over time. Dust and debris can accumulate, affecting functionality. It’s vital to clean and inspect brake parts regularly. Some vehicle owners forget to check the brake fluid level. Low fluid can hinder braking effectiveness. Simple actions, like flushing the brake system, can extend its lifespan.

Many drivers underestimate the importance of brake inspection. It is often overlooked until a problem arises. Regular maintenance is not just preventive; it enhances overall performance. Furthermore, inconsistent checks can lead to uneven pad wear. This can cause the car to pull to one side during braking, creating an unsafe driving situation. A routine maintenance schedule is key to ensuring safety and enhancing braking capabilities.

Safety Ratings and Regulatory Standards for Brake Components in 2026

In 2026, the focus on safety ratings and regulatory standards for brake components is paramount. The demand for reliable braking systems has never been higher. Vehicles must meet rigorous tests to ensure their braking performance. Standards vary globally but share a core goal: to protect lives. Manufacturers invest heavily to comply with these regulations, yet some still fall short.

Many consumers are unaware of how these standards impact their choices. For instance, the material quality of brake pads significantly affects overall safety. Not all components are created equal; some may even generate excessive dust or noise. This reflects a need for consumer education about what constitutes a safe brake system.

Regulatory bodies continuously update safety ratings based on real-world data. However, accountability lies with both manufacturers and buyers. Some companies may cut corners to reduce costs, which raises concerns. Ensuring that each component meets safety benchmarks is vital. As the automotive industry evolves, staying informed about these changes is crucial for safety-conscious drivers.

2026 Best Car Brake Parts for Safety and Performance Insights

| Brake Component Type | Material | Safety Rating | Performance Rating | Regulatory Standards Compliance |

|---|---|---|---|---|

| Brake Pads | Ceramic | 5 Stars | Excellent | DOT Approved |

| Brake Rotors | Cast Iron | 4 Stars | Very Good | SAE Standard |

| Brake Lines | Stainless Steel | 5 Stars | Outstanding | ISO 9001 Certified |

| Brake Fluid | Synthetic | 5 Stars | Excellent | DOT 5 Approved |

| Brake Calipers | Aluminum | 4 Stars | Very Good | FMVSS 135 Compliant |

Related Posts

-

Unlocking the Future: How Emerging Technologies are Revolutionizing the Motor Parts Industry

-

Best Car Engine Tips for Maximum Performance and Longevity

-

What is Parts Engine and How Does it Function?

-

How to Identify and Replace Essential Car Brake Parts for Safety

-

Top 10 Essential Engine Parts Every Car Owner Should Know About

-

Top 10 Essential Car Parts Every Car Owner Should Know About