How to Choose Engine Bearings for Optimal Performance?

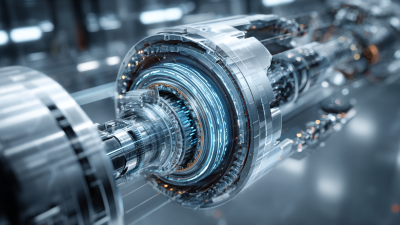

Choosing the right engine bearings is crucial for engine performance. These small components play a significant role in your vehicle's functionality. Engine bearings support the crankshaft and reduce friction with the connecting rods. When selecting engine bearings, consider factors such as material, size, and load capacity.

Different engines have unique requirements. Not all engine bearings are created equal. Some may improve performance but are not always suitable for all conditions. It's essential to review the specifications to ensure compatibility. Keep in mind, improper selection can lead to engine failure. This might seem trivial, yet many overlook it.

Many enthusiasts rush into decisions. They often choose based on limited information. This can result in costly mistakes. Reflection on personal needs and conditions is vital. The right engine bearings make a significant impact on engine longevity and efficiency. Prioritizing quality and fit will lead to optimal performance.

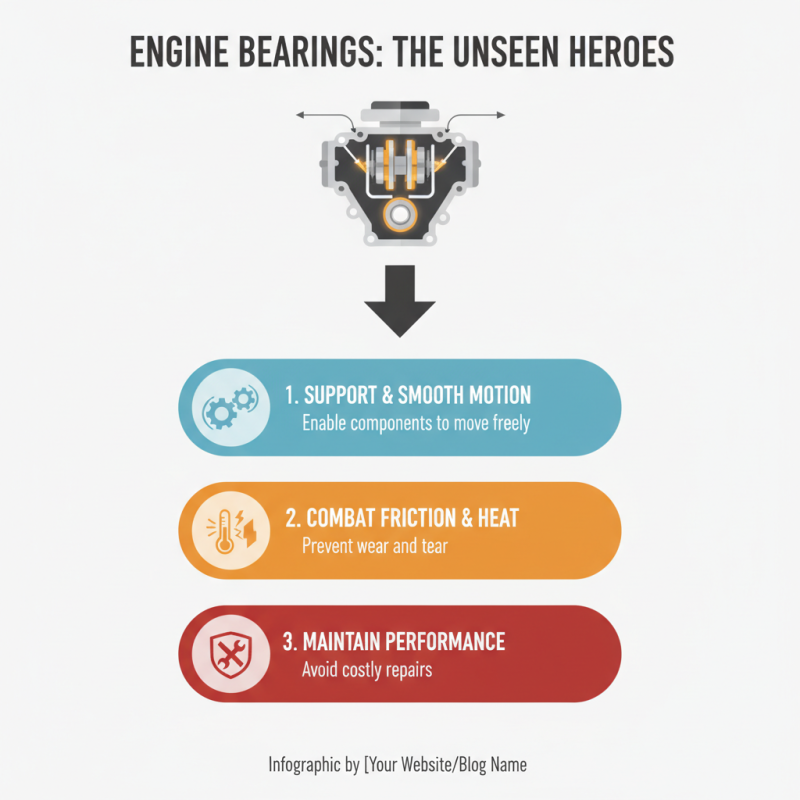

Understanding the Role of Engine Bearings in Performance

Engine bearings play a crucial role in your vehicle's performance. They support the engine components, allowing them to move smoothly and efficiently. When engine bearings wear out, it can lead to increased friction and heat. This affects the entire engine's functionality, leading you to face costly repairs or diminished performance.

Choosing the right engine bearings is essential. Different types accommodate varying loads and operating conditions. Pay attention to material quality, design, and dimensions. Even slight miscalculations can lead to significant problems down the line. Many overlook the impact of proper lubrication. Insufficient oil flow can exacerbate wear, reducing the lifespan of bearings.

Regular maintenance is often neglected. It's easy to forget about bearings until problems arise. Monitor engine sounds and performance closely. Any unusual vibrations or noises could signal bearing wear. Additionally, consider the driving conditions. Frequent stop-and-go city driving creates different stresses than long highway trips. Assess your needs, and make informed choices. The right bearings can enhance your engine's efficiency and longevity, but awareness is key.

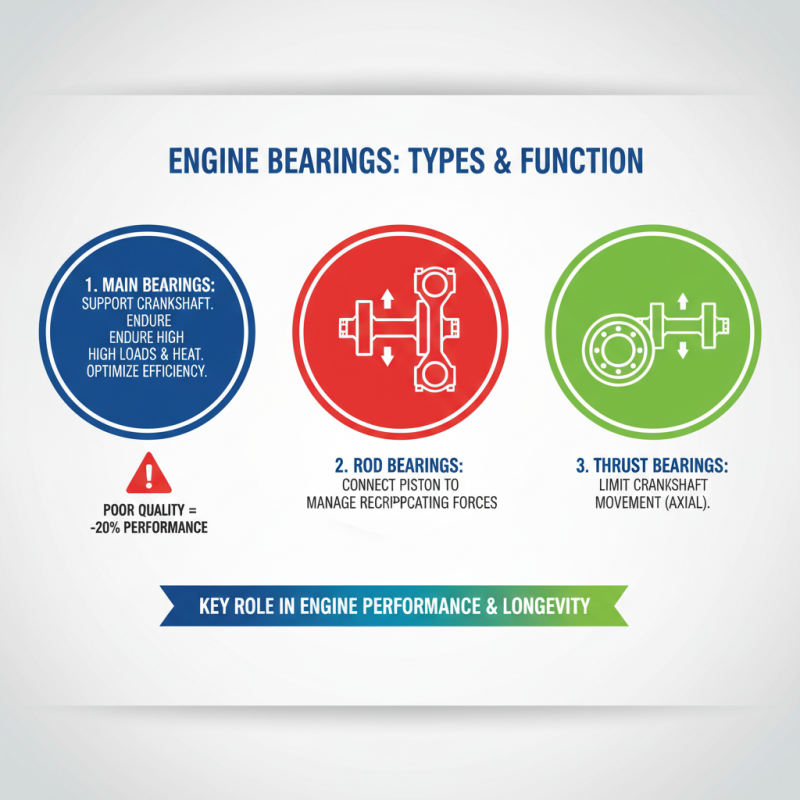

Types of Engine Bearings: Main, Rod, and Thrust Bearings

When considering engine bearings, it's essential to understand their types: main, rod, and thrust bearings. Each serves a unique function in engine performance. Main bearings support the crankshaft. They endure significant loads and must withstand intense heat. Optimal materials can extend their lifespan and improve efficiency. According to industry data, poor-quality main bearings can cause up to a 20% decrease in engine performance.

Rod bearings connect the connecting rods to the crankshaft. These bearings experience high stress and require precise clearance. They work in a hostile environment, constantly exposed to oil and combustion gases. A recent report highlights that over 15% of engine failures relate to rod bearing wear. Regular inspection can mitigate these risks, but many owners overlook this crucial maintenance aspect.

Thrust bearings, though less discussed, play a vital role. They control crankshaft movement and prevent lateral displacement. Neglecting their condition can lead to severe engine damage. Surprisingly, about 10% of engine rebuilds involve thrust bearing issues. Many enthusiasts underestimate this risk. Selecting the right engine bearings is more than a purchase; it’s a strategic choice for durability and performance.

Factors to Consider When Selecting Engine Bearings

Selecting engine bearings requires careful consideration of several factors to ensure optimal performance. One crucial aspect is the bearing material. Options vary from aluminum to bi-metal options and even composite materials. Each material has its unique properties that influence wear resistance and thermal conductivity. It's essential to match the material to your specific engine requirements.

Another significant factor is the clearance. Too much clearance may lead to inadequate oil pressure. On the other hand, too little can cause excessive heat. A precise fit is vital for maintaining performance and longevity. In some cases, measuring tools may not provide an accurate reading. A thorough inspection is necessary to avoid mistakes.

**Tip:** Always consider the intended use of your engine. Different applications require different bearing specifications. Street engines may not need the same performance requirements as racing engines.

Pay attention to the engine speed. Higher RPMs demand bearings that can handle the stress. It's important to review the manufacturer's guidelines on maximum engine speeds. Sometimes, these recommendations can be overlooked.

**Tip:** Consult experts or forums for insights. Peer reviews can reveal critical performance insights or shortcomings. Knowledge sharing can lead to better decision-making.

Engine Bearings Selection Factors

Material Options for Engine Bearings and Their Impact on Performance

When selecting engine bearings, the material choice significantly affects performance. Common materials include aluminum, copper-lead, and bi-metal bearings. Each option presents distinct advantages and challenges. Aluminum bearings often offer lightweight properties, contributing to improved fuel efficiency. However, they can wear faster under extreme conditions.

Copper-lead is frequently chosen for its high strength and low friction properties. According to a study by the International Journal of Engine Research, copper-lead bearings can endure high loads better than their aluminum counterparts. Still, they may require careful monitoring, as corrosion can occur over time.

Bi-metal bearings combine different materials, providing a balance of strength and durability. These bearings can achieve optimal performance in diverse applications. A recent report indicated that 70% of modern engines utilize bi-metal constructions. While they offer versatile performance, their manufacturing process can introduce inconsistencies. It’s essential to analyze the application requirements before making a final decision.

Installation Best Practices for Engine Bearings to Ensure Longevity

When installing engine bearings, precision is crucial. Misalignment can lead to premature wear and failure. A study by the Society of Automotive Engineers found that proper installation can increase bearing life by up to 30%. It's important to check for any debris or contaminants on the surfaces. Cleanliness plays a vital role in ensuring longevity.

Use the correct torque specifications. Over-tightening can deform bearings, leading to performance issues. Conversely, under-tightening can lead to play, causing friction and heat build-up. According to a report from the International Journal of Engine Technologies, consistent torque application reduces the risk of bearing fatigue. Regular inspections should become a routine part of engine maintenance.

It's also important to choose the right oil type. The viscosity affects bearing lubrication. A research paper indicated that improper oil can decrease bearing life by as much as 15%. Pay attention to the environment where the engine operates. Extreme temperatures can impact bearing integrity. Always consider these elements during installation. Small oversights can result in significant consequences.

How to Choose Engine Bearings for Optimal Performance? - Installation Best Practices for Engine Bearings to Ensure Longevity

| Criteria | Description | Recommended Material | Installation Tips |

|---|---|---|---|

| Bearing Type | Select the right type of bearing based on engine requirements. | Steel, Aluminum | Ensure compatibility with crankshaft and connecting rods. |

| Clearance | Proper clearance is essential for oil flow and to prevent engine failure. | Copper-lead, Bi-metallic | Use a micrometer to measure and confirm clearance accurately. |

| Oil Type | The choice of oil affects bearing performance significantly. | Synthetic, High-Viscosity | Follow the manufacturer’s recommendations for oil type. |

| Installation Environment | Cleanliness during installation is critical to longevity. | N/A | Avoid dust and contaminants; use a clean workshop. |

| Tightening Sequence | Follow the correct tightening sequence to distribute load. | N/A | Consult service manuals for appropriate sequence. |

Related Posts

-

Understanding the Importance of Engine Bearings for Enhanced Vehicle Performance

-

2025 Top 5 Essential Car Tools Every Vehicle Owner Must Have

-

Why Quality Automotive Parts Are Essential for Your Vehicle's Performance

-

Top 10 Car Engine Parts You Should Know About?

-

10 Essential Tips for Choosing the Right Automotive Parts for Your Vehicle

-

Unlocking the Future: How Emerging Technologies are Revolutionizing the Motor Parts Industry