How to Choose the Right Engine Bearings for Your Vehicle?

Choosing the right engine bearings is crucial for vehicle performance and longevity. Engine bearings play a significant role in reducing friction. A study by the Society of Automotive Engineers indicates that incorrect bearing selection can lead to a 25% loss in engine efficiency. This raises concerns for vehicle owners and mechanics alike.

Engine bearings are not one-size-fits-all. Each engine design has specific requirements based on load and operating conditions. For example, high-performance engines may require specialized materials to withstand extreme conditions. Inconsistent choices can result in premature wear or failure.

Reflecting on the selection process is essential. Many enthusiasts overlook the importance of quality bearings, focusing instead on aesthetics or brand reputation. A report from Engine Builder magazine highlighted that 40% of engine failures are traced back to improperly selected parts, including bearings. Understanding the specifics can help in making informed decisions, ensuring both performance and reliability.

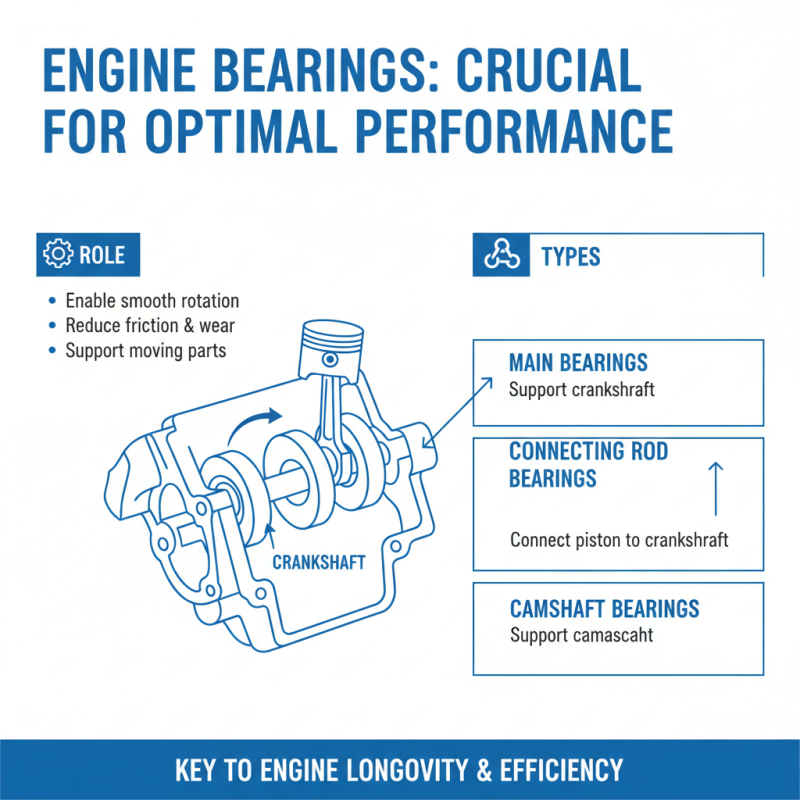

Understanding the Function of Engine Bearings in Your Vehicle

Engine bearings are crucial components in a vehicle's engine. They support the crankshaft and connect it to the engine block. This connection allows the crankshaft to rotate smoothly. Proper function of these bearings is vital for engine performance. When they wear out, it can lead to serious problems.

These components reduce friction and help distribute load. A car engine operates under immense pressure and heat. Bearings withstand this stress daily. If they fail, it can cause metal-to-metal contact. This results in decreased efficiency and possible engine damage. Signs of wear include knocking sounds or decreased power.

Choosing the right engine bearings requires attention to detail. Ensure the correct size and material. Each vehicle has specific requirements based on its design. Ignoring these factors can lead to costly repairs. Quality bearings are an investment in the engine's future. Do not underestimate their importance in maintaining engine health.

Identifying the Different Types of Engine Bearings Available

Engine bearings play a crucial role in your vehicle's performance. They provide a surface for the crankshaft and connecting rods to rotate smoothly. Understanding the different types of engine bearings is vital for optimal engine function. There are mainly three types of engine bearings: main bearings, connecting rod bearings, and camshaft bearings.

Main bearings support the crankshaft. They ensure proper alignment and reduce friction. Connecting rod bearings link the crankshaft to the connecting rods. They endure significant forces during operation. Camshaft bearings support the camshaft’s movement and control valve timing. Each type has specific material compositions, such as aluminum, bi-metal, or tri-metal. A recent study by the Engine Builders Association highlights that around 70% of engine failures are linked to bearing issues.

Choosing the right bearings can enhance performance. Many factors influence this decision. These include intended use, operating conditions, and engine modifications. Data shows that high-performance engines benefit from specialized bearing materials. For instance, bearings with better heat resistance can prevent premature wear. However, picking the wrong bearings might lead to catastrophic engine damage. It's essential to assess your specific needs carefully. Understanding the consequences of poor choices should guide your selection process.

Factors to Consider When Selecting Engine Bearings

When selecting engine bearings, several critical factors should be considered. The first is material composition. Bearings are typically made from aluminum, copper, or bi-metallic materials. Each has unique characteristics. For example, aluminum bearings are lightweight and offer good thermal conductivity, while copper bearings provide better wear resistance. Data from automotive engineering reports indicate that using high-quality materials can extend engine life by up to 30%.

Next is the bearing clearance. This refers to the gap between the bearing and the journal. Too much clearance can lead to excessive oil flow and lower pressure. On the other hand, too little clearance can result in overheating. Studies show that an optimal clearance range can significantly impact an engine's efficiency. The ideal range can vary between 0.001 and 0.003 inches, depending on the application.

Finally, consider the intended use of the vehicle. Different engines have different performance requirements. A performance engine may need specialized bearings designed to withstand high stresses. In contrast, a regular commuter vehicle might prioritize durability over high performance. According to industry data, mismatching bearing types with engine requirements can reduce performance by up to 15%. Thus, careful selection based on specific needs is crucial for optimal engine function.

Choosing the Right Engine Bearings: Key Factors

Evaluating Compatibility with Your Vehicle's Engine Specifications

Choosing the right engine bearings involves understanding your vehicle's specifications. Each engine is designed with unique tolerances and performance requirements. Compatibility is crucial when selecting bearings since incorrect choices can lead to serious engine damage.

Start by consulting your engine's manual for specifications. Look for details like bearing size, material type, and clearance requirements. Not all bearings are created equal. Some might seem compatible but can affect performance. Pay attention to engine wear patterns and check for any signs of prior damage.

Many choose based on price alone. This can lead to regrets later. Consider durability and quality over just saving a few bucks. A bearing that fits poorly can cause knock or even engine failure. It’s vital to match the bearings precisely to your engine’s needs for long-lasting performance.

Tips for Proper Installation and Maintenance of Engine Bearings

Choosing the right engine bearings is essential for your vehicle's longevity. Proper installation of these components is crucial. A 2022 study by the Automotive Research Group shows that improper installation can lead to a 35% increase in wear and tear. Make sure the bearings are clean and free from debris before installation. Use assembly lube to ensure a proper fit.

When installing, pay attention to the torque specifications. Over-torquing can deform the bearing, while under-torquing can cause motion. Each type of bearing has specific requirements. For example, a standard clearance for mainstream applications is 0.0015 to 0.0025 inches. Verify these specs in your repair manual.

Maintenance plays a significant role in bearing life. Regular oil changes help reduce contaminant build-up. Industry data indicates that 60% of bearing failures stem from inadequate lubrication. Monitor your oil levels closely. If you notice unusual noise or a drop in performance, it’s time to inspect your bearings. Ignoring these signs can result in costly repairs down the road.

How to Choose the Right Engine Bearings for Your Vehicle?

| Bearing Type | Material | Applications | Installation Tips | Maintenance Tips |

|---|---|---|---|---|

| Main Bearings | Bimetal | Engines with high load | Ensure proper lubrication before installation | Regular oil changes to prevent wear |

| Rod Bearings | Lead-Copper Alloy | Sport and performance engines | Check for proper clearance | Monitor engine temperature |

| Camshaft Bearings | Steel-backed | High-performance engines | Align accurately with the shaft | Lubricate before startup |

| Thrust Bearings | Bronze | Applications with axial loads | Ensure flatness of gasket surfaces | Check periodically for play |

Related Posts

-

The Hidden Role of Car Bearings in Ensuring Smooth and Safe Driving

-

Top Trends in Car Bearings for Enhanced Vehicle Performance

-

Top 10 Distributor Parts You Need to Know About?

-

What is an Engine Bearing and Why is it Important?

-

How to Choose the Right Automotive Parts for Your Vehicle Maintenance

-

What is a Steering System and How Does It Work?