How to Diagnose Common Fuel System Issues?

A well-functioning fuel system is critical for any vehicle's performance. When issues arise within this system, it can lead to poor fuel efficiency and engine problems. Understanding how to diagnose common fuel system issues is vital for all car owners.

Often, symptoms like stalling, rough idling, or decreased acceleration point to fuel system failures. These problems can stem from clogged fuel filters or failing fuel pumps. It is essential to identify these issues promptly to prevent further damage.

Many drivers overlook these signs, assuming they are minor glitches. But ignoring them can exacerbate problems, leading to costly repairs. By taking time to assess the fuel system, one can avoid major headaches down the road. Addressing these issues early on can ensure a smoother driving experience.

Understanding the Basics of Fuel System Components and Their Functions

Understanding the fuel system is essential for diagnosing common issues. A vehicle's fuel system comprises several key components. These include the fuel tank, fuel pump, fuel filter, and fuel injectors. Each plays a vital role in ensuring that fuel reaches the engine efficiently.

The fuel pump sends gasoline from the tank to the injectors. If it fails, you might notice engine sputtering or failure to start. The fuel filter is another critical part. It cleans the fuel before it reaches the engine. A clogged filter can cause performance issues. Symptoms may include stalling or poor acceleration.

Fuel injectors are responsible for delivering the right amount of fuel into the combustion chamber. If these become dirty or malfunction, your engine may run inefficiently. Issues like poor fuel economy or rough idling could suggest injector problems. Understanding these components can help you identify potential issues more effectively.

Common Symptoms of Fuel System Problems: How to Identify Issues

When it comes to diagnosing fuel system issues, being aware of common symptoms can save time and hassle. A rough idle is often the first sign that something is wrong. You might notice the engine shaking or stalling. This isn’t just annoying; it can lead to bigger problems. Ignoring this symptom could cost you more down the line.

Another common issue is decreased fuel efficiency. If your car seems to consume more fuel than usual, it’s a red flag. Pay attention to how often you fill up. Strange noises from the fuel pump can also indicate trouble. If you hear whining or clicking, act fast. It may not be a simple fix.

Don't overlook warning lights. The check engine light could be a hint of fuel system trouble. If you see this, consider getting a diagnostic scan. Regularly inspecting your fuel filter is also key. A clogged filter can create significant flow issues. Make time for maintenance. Addressing the symptoms early can help you avoid unexpected breakdowns.

Step-by-Step Diagnosis of Fuel System Issues: Tools and Techniques

Diagnosing fuel system issues requires the right tools and techniques. A comprehensive approach is essential. Start with a fuel pressure gauge. This tool helps identify if the fuel pump is delivering proper pressure. Studies show that about 18% of fuel system failures are due to low fuel pressure. Accurate readings can save time and reduce guesswork.

Next, inspect the fuel filter. A clogged filter may restrict fuel flow. Studies indicate that a dirty fuel filter can reduce engine performance by up to 30%. Use specialized tools to remove and check it. Also, listen for unusual sounds from the fuel pump. Strange noises can indicate wear or failure.

Examine the fuel injectors too. They can become clogged or malfunction over time. Reports suggest that faulty injectors account for 12% of engine performance issues. Cleaning or replacing them can restore efficiency. It’s important to remember that even seasoned mechanics can overlook simple issues. A systematic approach helps catch these problems early.

How to Diagnose Common Fuel System Issues?

| Issue | Symptoms | Tools Needed | Diagnosis Steps |

|---|---|---|---|

| Clogged Fuel Filter | Engine sputters, Difficulty starting | Wrench, Fuel pressure gauge | 1. Locate the fuel filter 2. Check for pressure drop 3. Replace if necessary |

| Faulty Fuel Pump | No start, Whining noise from tank | Multimeter, Fuel pressure gauge | 1. Check electrical connections 2. Measure voltage to pump 3. Test fuel pressure |

| Leaking Fuel Injector | Rough idle, Fuel smell | O-ring replacement kit, Cleaning solution | 1. Inspect injectors visually 2. Conduct a leak test 3. Replace O-rings if leaking |

| Dirty Fuel Lines | Poor acceleration, Engine misfire | Fuel line cleaner, Hose clamp | 1. Disconnect fuel line 2. Flush with cleaner 3. Reconnect and test |

| Vacuum Leak | High idle, Poor fuel economy | Vacuum gauge, Hose replacement kit | 1. Check all vacuum lines 2. Use gauge to find leaks 3. Replace faulty hoses |

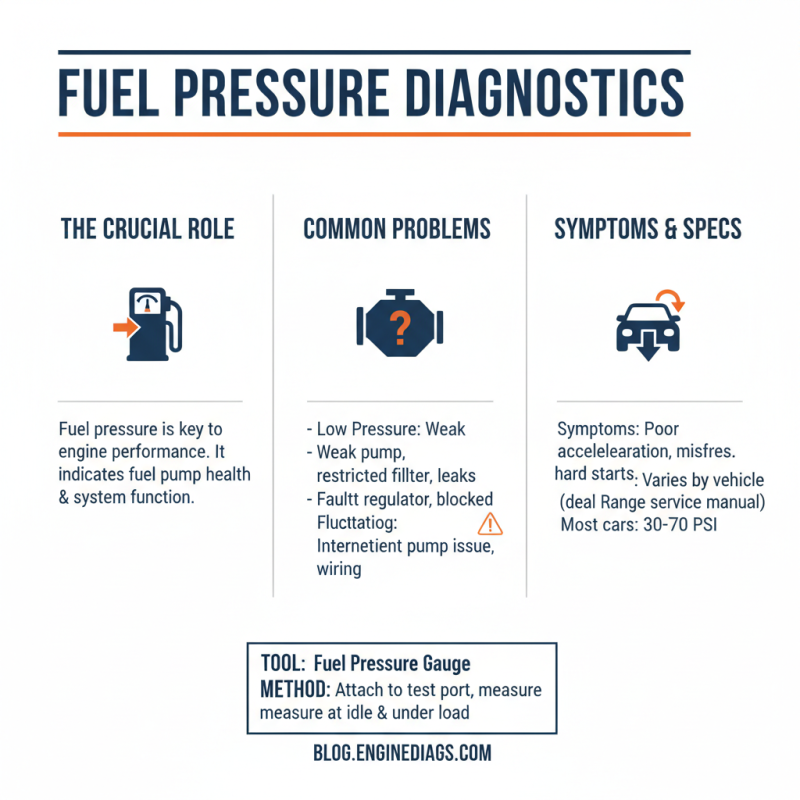

Analyzing Fuel Pressure: Key Data for Diagnosing Fuel Delivery Problems

When diagnosing fuel delivery problems, analyzing fuel pressure is crucial. Fuel pressure provides key insights into the system's functionality. A malfunctioning fuel pump may not generate enough pressure, leading to poor engine performance. The ideal pressure level varies by vehicles, but most require a specific range to run smoothly.

To start, gather a fuel pressure gauge. Attach it to the fuel rail. Turn the ignition without starting the engine. Observe the reading. If it’s below the recommended level, trouble might exist within the pump or the filter. Pay attention to any sudden drops in pressure. This could indicate leaks or failing injectors.

Always check connections and hoses for wear. Small cracks can lead to significant pressure loss. Observing fuel pressure alone does not provide all answers. Consider other factors, such as air intake and engine temperature. Fuel system diagnostics can often feel overwhelming. There are always areas needing further exploration. Embrace the imperfections in the process. Every test brings new questions.

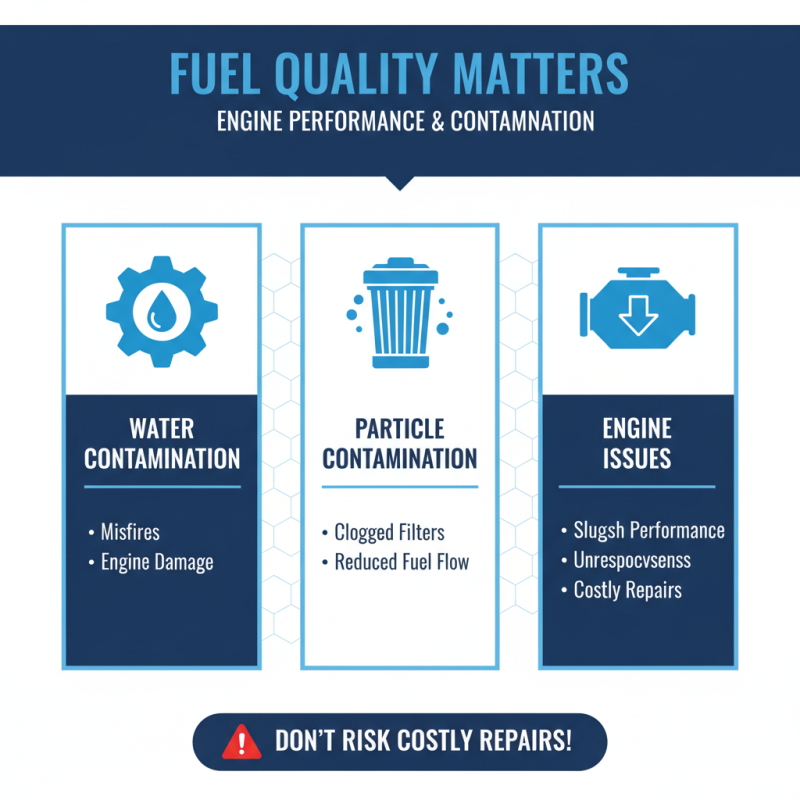

Evaluating Fuel Quality and Contamination: Impact on Engine Performance

When evaluating fuel quality, it's essential to consider how contamination affects engine performance. Low-quality fuel can lead to several engine issues. For instance, water in the fuel can cause misfires. Tiny particles can clog fuel filters, reducing flow. This can make engines feel sluggish and unresponsive. Each drop of contaminated fuel could lead to costly repairs.

It’s crucial to regularly check fuel systems for impurities. Look for any signs of discoloration or floating debris in the fuel tank. Did you notice any rough idling? This could be a sign of poor fuel quality. Keeping an eye on fuel cleanliness can prevent performance issues down the road. Perhaps you’ve neglected this aspect before, but now is a good time to reflect on it. Regular maintenance is key. It's easy to overlook, but essential for long-term health.

Related Posts

-

10 Essential Tips for Maintaining Your Fuel System?

-

How to Choose the Right Automotive Parts for Your Vehicle Maintenance

-

2025 Top 5 Essential Car Tools Every Vehicle Owner Must Have

-

How to Choose the Best Motor Parts for Your Vehicle in 2025

-

10 Essential Tips for Choosing the Right Automotive Parts for Your Vehicle

-

Top 10 Car Engine Parts You Should Know About?