Unlocking the Future: How Emerging Technologies are Revolutionizing the Motor Parts Industry

In today's rapidly evolving technological landscape, the motor parts industry stands on the brink of a transformative revolution. Emerging technologies are not just reshaping how motor parts are manufactured; they are redefining the entire value chain from design to distribution. Innovations such as 3D printing, artificial intelligence, and IoT connectivity are enabling manufacturers to produce high-quality components with unprecedented efficiency and customization. This article will delve into the various facets of these advancements, exploring how they drive sustainability, enhance performance, and improve supply chain management within the motor parts sector.

By unlocking the potential of these emerging technologies, industry stakeholders can navigate the complexities of modern automotive demands, ultimately paving the way for a smarter and more sustainable future in motor parts.

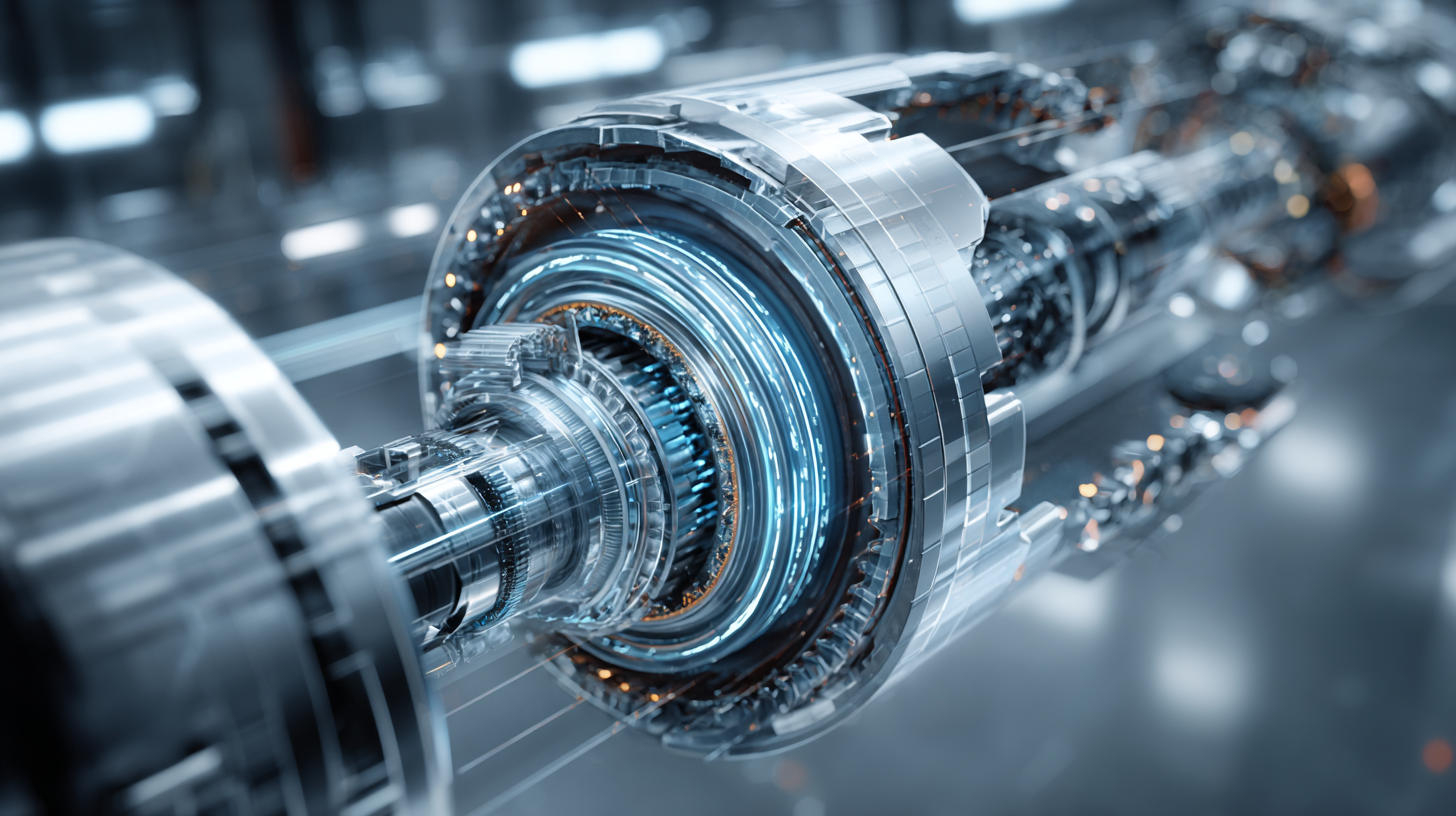

Emerging Technologies Reshaping Production Processes in the Motor Parts Industry

The global auto parts manufacturing market is undergoing a significant transformation driven by emerging technologies. As the market expands, projected to grow from USD 701.57 billion in 2024 to USD 1195.4 billion by 2032, manufacturers are increasingly adopting innovations that enhance production processes. Automation, artificial intelligence, and advanced materials are at the forefront, enabling suppliers to improve efficiency and reduce waste. This shift not only meets the rising global demand for automotive components but also aligns with trends toward electrification and sustainability.

THACO Industries exemplifies this movement by investing in a regional-scale component manufacturing hub, fostering collaboration within the supporting industry. Such initiatives signal a robust push toward optimizing production capabilities through the integration of innovative manufacturing techniques, enhancing supply chain resilience in the face of changing market dynamics. By leveraging these emerging technologies, companies can transform their operations, ensuring they remain competitive in a rapidly evolving automotive landscape.

The Role of Artificial Intelligence in Enhancing Quality Control in Manufacturing

Artificial Intelligence (AI) is transforming the motor parts industry by significantly enhancing quality control processes in manufacturing. According to a recent report by McKinsey, companies that implement AI-based quality control systems can improve defect detection rates by up to 90%, drastically reducing production waste and rework costs. AI algorithms analyze vast amounts of data from manufacturing processes in real time, allowing for immediate identification of anomalies and deviations from quality standards, ensuring that only top-quality parts reach the market.

Moreover, a study from Deloitte highlights that integrating AI-powered predictive analytics in quality control can lead to a 25% increase in operational efficiency. By utilizing machine learning models, manufacturers can predict potential failures based on historical data, thereby preventing issues before they arise. This not only enhances the overall quality of motor parts but also contributes to a more sustainable manufacturing process by minimizing the environmental impact associated with defective products. As the industry continues to embrace these emerging technologies, the role of AI in quality control will undoubtedly be pivotal in shaping the future of motor parts manufacturing.

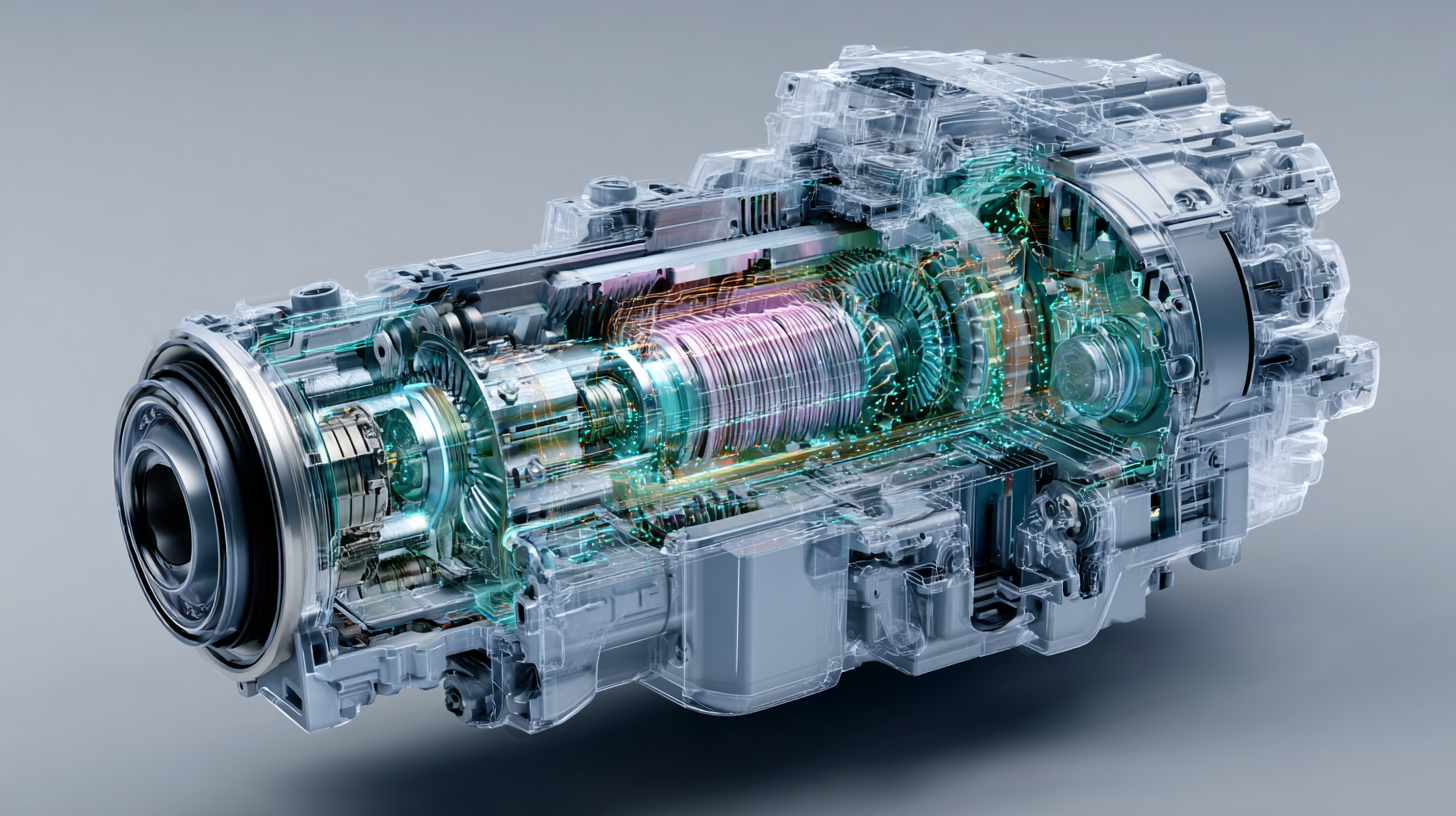

3D Printing: Transforming Parts Prototyping and Customization in the Automotive Sector

Emerging technologies are significantly transforming the automotive sector, particularly through the application of 3D printing. This innovative manufacturing process enables the rapid prototyping of motor parts, allowing engineers to create and test designs in a fraction of the time traditionally required. With 3D printing, companies can swiftly iterate on designs, leading to enhanced efficiency and reduced costs in the development process. The ability to produce prototypes on-demand minimizes waste and can streamline inventory management, fundamentally changing how parts are developed and produced.

Moreover, 3D printing offers unparalleled opportunities for customization in the automotive industry. Manufacturers can easily tailor parts to meet specific customer needs or preferences, leading to a more personalized approach in vehicle design. This level of customization not only enhances customer satisfaction but also encourages innovation, as unique and intricate designs can be brought to life without the constraints of conventional manufacturing methods. As the technology continues to advance, 3D printing is set to redefine the standards of production, paving the way for a more adaptable and responsive motor parts industry.

Unlocking the Future: 3D Printing in the Automotive Sector

This chart illustrates the growing adoption of 3D printing technologies in the automotive sector, highlighting the percentage of companies utilizing 3D printing for parts prototyping and customization from 2018 to 2023.

Blockchain Technology: Ensuring Supply Chain Transparency in Motor Parts Distribution

Blockchain technology is poised to transform the motor parts industry by ensuring unparalleled transparency in supply chain management. As the demand for genuine and quality motor parts grows, the ability to trace the origin and journey of each component becomes essential. Blockchain serves as a decentralized ledger that records transactions in a tamper-proof manner, allowing manufacturers, suppliers, and consumers to verify the authenticity of the parts. This technology helps to mitigate risks associated with counterfeit products, ensuring that the components reaching the market have been sourced ethically and meet rigorous quality standards.

Moreover, blockchain facilitates real-time tracking of motor parts within the supply chain, providing stakeholders with instant access to crucial information. This includes details surrounding production dates, shipping logistics, and compliance with regulatory standards. By utilizing smart contracts, companies can automate processes, streamline operations, and reduce human errors or delays. As manufacturers and suppliers adopt blockchain for their transactions, they can build trust with their customers, enhancing brand loyalty and securing a competitive edge in a rapidly evolving market. In an industry where precision and reliability are paramount, the integration of blockchain technology will not only redefine distribution practices but also pave the way for innovation in motor parts management.

Unlocking the Future: How Emerging Technologies are Revolutionizing the Motor Parts Industry

| Technology | Application | Benefits | Challenges |

|---|---|---|---|

| Blockchain | Supply Chain Transparency | Enhanced trust and verification | Scalability of technology |

| IoT | Real-time monitoring | Improved operational efficiency | Data security concerns |

| AI | Predictive maintenance | Reduced downtime | Implementation complexity |

| 3D Printing | On-demand parts production | Cost-effective production | Material limitations |

| Augmented Reality | Maintenance and training | Enhanced user experience | Public acceptance |

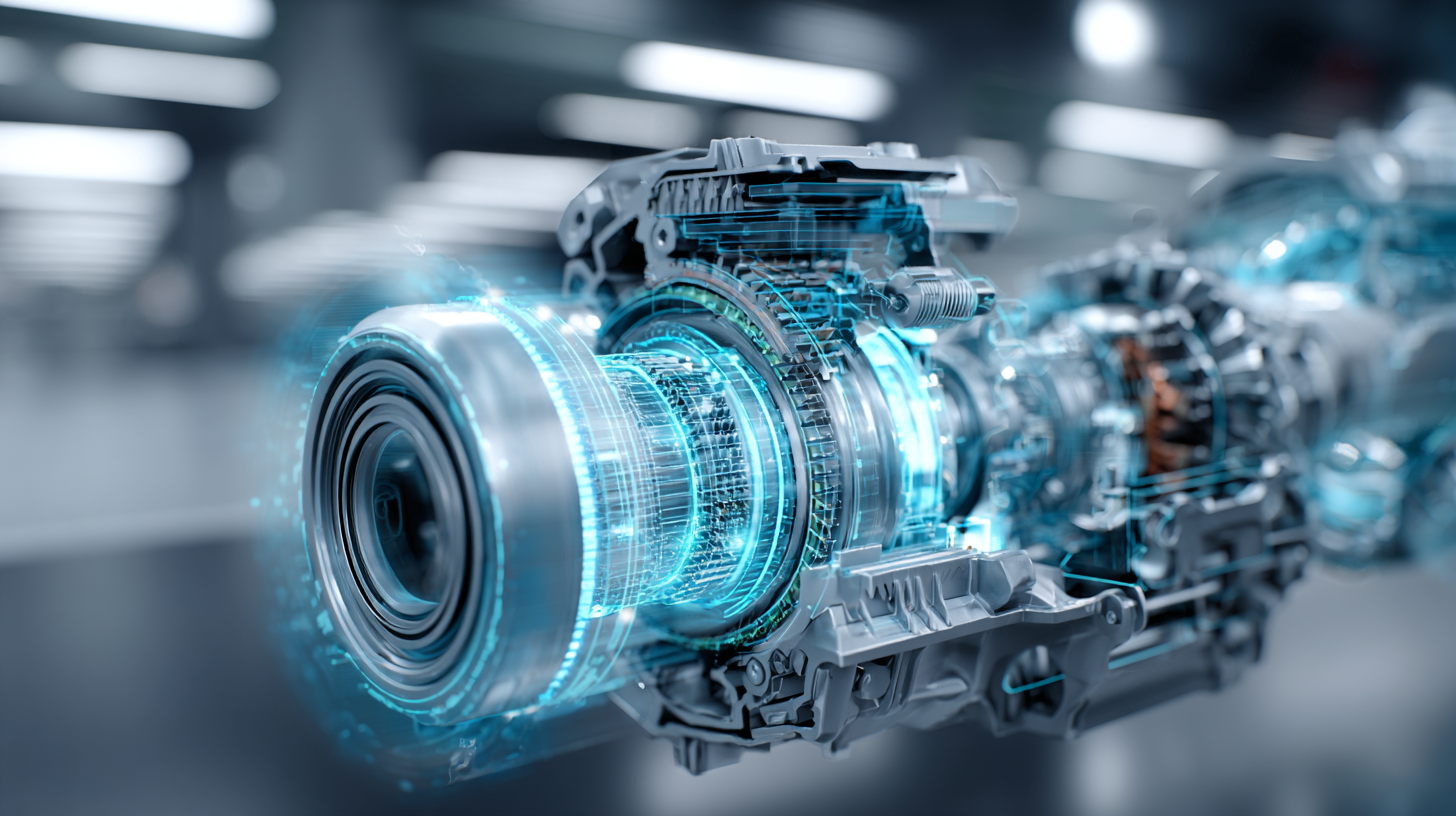

The Impact of IoT on Predictive Maintenance and Efficiency in Motor Parts Systems

The integration of the Internet of Things (IoT) into the motor parts industry is transforming how businesses approach predictive maintenance and operational efficiency. By leveraging smart sensors and connected devices, companies can continuously monitor the performance of machinery and components. This real-time data not only enables the early detection of potential failures but also allows for data-driven decision-making that optimizes maintenance schedules. As a result, organizations can reduce downtime, extend the lifespan of their equipment, and cut operational costs significantly.

The integration of the Internet of Things (IoT) into the motor parts industry is transforming how businesses approach predictive maintenance and operational efficiency. By leveraging smart sensors and connected devices, companies can continuously monitor the performance of machinery and components. This real-time data not only enables the early detection of potential failures but also allows for data-driven decision-making that optimizes maintenance schedules. As a result, organizations can reduce downtime, extend the lifespan of their equipment, and cut operational costs significantly.

Tips: To successfully implement IoT in your motor parts systems, start with a pilot program focusing on critical machinery. Ensure that you select sensors that are compatible with your existing infrastructure and train your staff to analyze the data effectively. Regularly review and update your predictive maintenance strategies to adapt to new insights gained from IoT analytics.

Furthermore, the efficiency gains from IoT integration also extend to supply chain management. By tracking inventory levels and usage patterns in real-time, businesses can streamline ordering processes and minimize excess stock. This not only optimizes resource allocation but also enhances responsiveness to market demands.

Tips: Consider using cloud-based IoT platforms for better scalability and data management. Collaborate with suppliers to integrate their systems with yours, allowing for seamless data sharing that can further enhance supply chain efficiency.

Related Posts

-

Understanding the Role of Car Distributors: Your Guide to a Smooth Automotive Supply Chain

-

Ultimate Guide to Choosing the Best Brake Parts for Your Vehicle

-

Discover the Essential Car Pieces Every Vehicle Owner Should Know About

-

The Hidden Role of Car Bearings in Ensuring Smooth and Safe Driving

-

Exploring Key Car Factors: How They Influence Your Vehicle’s Performance and Value