What is an Engine Bearing and Why is it Important?

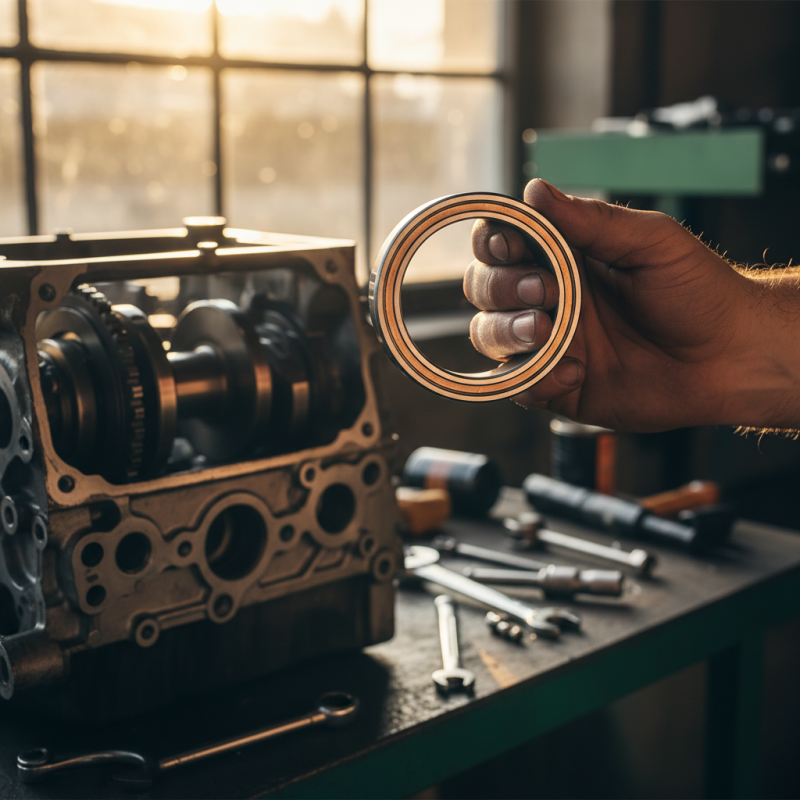

Engine bearings play a crucial role in the performance and longevity of engines. According to industry expert Dr. James Carter, "Engine bearings are the unsung heroes of machinery." They ensure smooth motion while minimizing friction between moving parts. Without them, engines would struggle to function properly.

The significance of engine bearings cannot be overstated. They support the crankshaft and allow for efficient power transfer. Without proper functioning bearings, engines face wear and tear, leading to costly repairs. Imagine an engine grinding to a halt due to a faulty bearing. It’s a nightmare scenario that many car owners fear.

In practice, selecting the right engine bearings can be challenging. Factors such as material, size, and design all influence their effectiveness. It's worth considering how often these components need inspection and replacement. Proper maintenance can extend the life of engine bearings, but many overlook this vital step. Ignoring this can lead to engine failure when least expected.

What is an Engine Bearing?

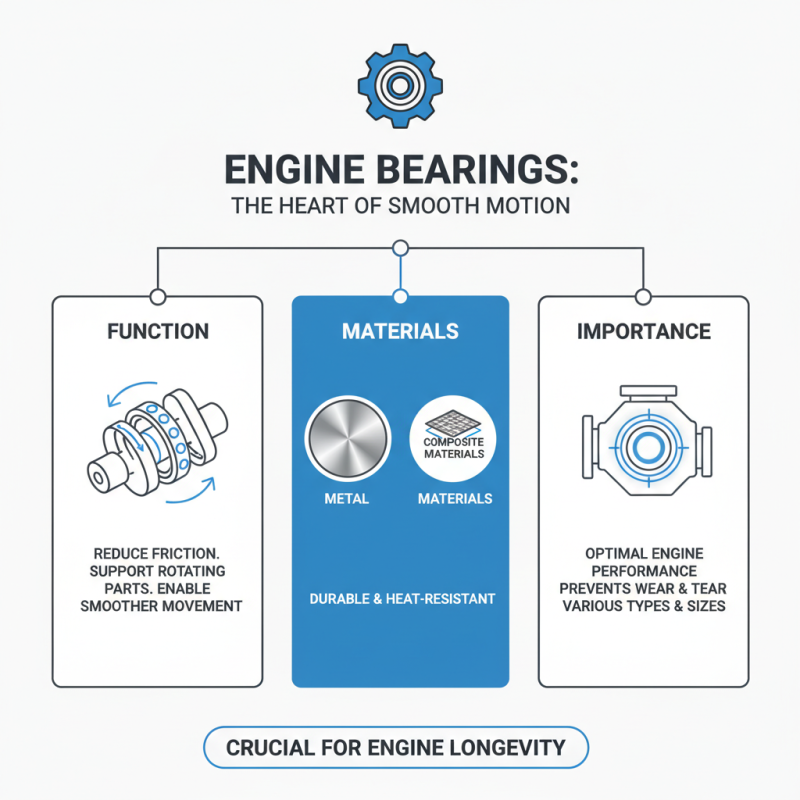

An engine bearing is a crucial component that supports the rotating parts of an engine. It reduces friction, allowing smoother movement. Bearings are typically made from materials such as metal or composite materials. They come in various shapes and sizes. Each type serves a specific function. A well-functioning bearing is vital for engine performance.

Without proper lubrication, bearings can wear out quickly. This leads to increased friction and engine damage. Regular maintenance is essential. Check oil levels frequently. Change the oil as recommended. Poor maintenance practices can result in costly repairs.

Tips: Always use the right oil type for your engine. Overheating may indicate bearing issues. Listen for unusual noises while driving; they can signal trouble. Keep an eye on odd vibrations. These signs may help catch problems early. Ignoring them can lead to significant engine failure.

Types of Engine Bearings and Their Functions

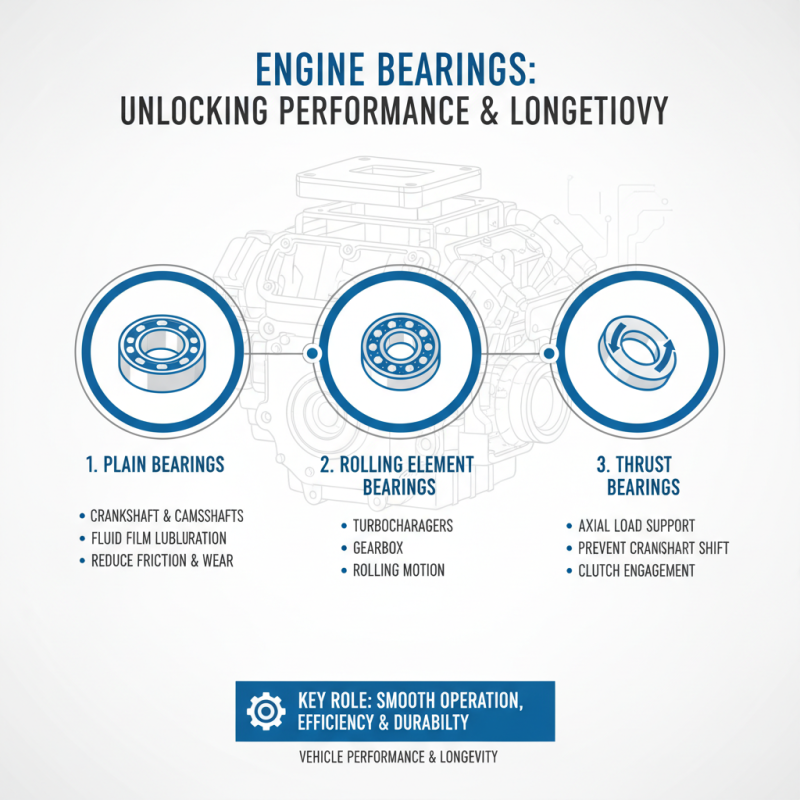

Engine bearings play a vital role in vehicle performance and longevity. They are crucial for the smooth operation of engine components. There are several types of engine bearings, each serving a specific function. The most common types include plain bearings, rolling element bearings, and thrust bearings.

Plain bearings are often used in locations where a sliding motion occurs. They reduce friction between moving parts. According to a report by the Society of Automotive Engineers, around 20% of engine failures are linked to bearing issues. Rolling element bearings, on the other hand, use balls or rollers to support loads. They are efficient but can be more complex to install. Thrust bearings help handle axial loads, preventing movement that could cause damage.

The choice of bearing type can greatly affect engine performance. For example, a poorly designed bearing can lead to increased wear and heat. This can shorten engine life and reduce efficiency. Some reports suggest that properly installed bearings can improve engine efficiency by up to 5%. However, improper handling during installation often goes unnoticed. Small mistakes lead to significant long-term consequences.

The Role of Engine Bearings in Engine Performance

Engine bearings play a crucial role in the overall performance of an engine. They reduce friction between the moving parts, allowing for smoother operation. With less friction, components can move freely. This reduces wear and tear, ultimately extending the engine's lifespan.

When engine bearings wear out, they can cause serious issues. Increased friction leads to overheating. Overheating, in turn, can warp engine components. In extreme cases, it may even result in engine failure. Regular maintenance is vital. An overlooked bearing can have dire consequences. Small problems can escalate quickly, leading to costly repairs.

Poor lubrication can also affect bearing performance. Insufficient oil flow increases metal-to-metal contact. This contributes to quick wear. Mechanics often overlook this detail. Ignoring it can lead to catastrophic damage. Engine bearings are small but critical. They are a testament to how minor components can impact an entire system.

Importance of Engine Bearings in Engine Performance

Common Issues Related to Engine Bearings

Engine bearings play a crucial role in vehicle performance. They support the moving parts of the engine, allowing for smooth operation. However, several common issues can affect their functionality. One major problem is wear and tear. Over time, oil degradation can lead to inadequate lubrication. This can cause the bearings to fail.

Another issue is contamination. Dirt and debris can infiltrate the engine, causing damage to bearings. If left unchecked, this can result in severe engine problems. Strange noises or vibrations may signal that a bearing issue is developing. Regular maintenance can help detect these problems early.

**Tip:** Always check oil levels. Low oil can accelerate bearing wear.

Sometimes, installing bearings incorrectly can lead to serious issues. Poor alignment can create excessive friction. This friction can lead to overheating and premature failure. If you notice unusual noises, address them quickly.

**Tip:** Keep an eye on engine temperature. High temperatures can lead to bearing issues.

Lastly, always be aware of your driving habits. Aggressive driving can put extra stress on engine components. This stress can affect bearing longevity. Pay attention to warning signs and act promptly.

Maintenance and Replacement of Engine Bearings

Engine bearings play a critical role in protecting the engine's moving parts. They reduce friction, support loads, and ensure smooth operation. Over time, engine bearings can wear out due to heat and constant pressure. That's why regular maintenance is essential.

Regular inspection of engine bearings can save you from costly repairs. Check for wear signs, such as noise or vibrations. Change the oil frequently to ensure proper lubrication. A clean system will help prolong bearing life.

Tips for maintenance: Listen for unusual sounds, and monitor engine performance. These signs might indicate bearing issues. Replace bearings as needed, and consider using quality lubricants. Remember, neglecting these parts can lead to more significant engine problems. Keeping a close eye on them is wise.

Related Posts

-

Understanding the Importance of Engine Bearings for Enhanced Vehicle Performance

-

How to Choose Engine Bearings for Optimal Performance?

-

Top 10 Engine Bearings You Should Know About?

-

How to Identify and Replace Essential Car Brake Parts for Safety

-

Top Trends in Car Bearings for Enhanced Vehicle Performance

-

2026 Top Distributor Parts for Enhanced Performance and Reliability?