Top 10 Distributor Parts You Need to Know About?

Understanding distributor parts is crucial for anyone involved in automotive repair or maintenance. These components play a significant role in engine performance. This article explores the top 10 distributor parts every enthusiast should know.

Distributor parts are intricate yet essential. Each part has a distinct function. The rotor helps direct electrical current, while ignition wires transfer this energy. Poor quality components can lead to misfires or reduced power.

Many overlook the importance of these parts until an issue arises. Regular checks can prevent costly repairs. Awareness and knowledge about distributor parts can enhance both vehicle efficiency and longevity. Let's dive into the key parts that influence your engine's performance.

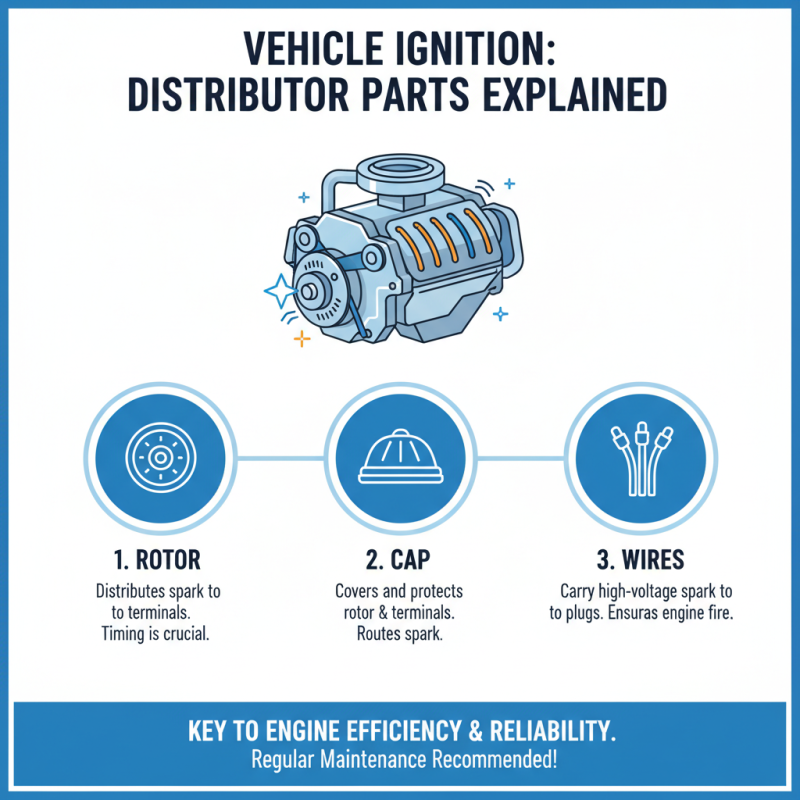

Key Components of Distributor Parts for Automotive Systems

Understanding the essential components of distributor parts in automotive systems is critical for performance and reliability. Distributors manage the electrical current that ignites the engine. Key elements include the rotor, cap, and ignition coil. Each component plays a significant role in ensuring optimal engine function.

Recent industry reports indicate that high-quality rotors can improve firing efficiency by 15%. A poorly functioning rotor can lead to misfires and decreased fuel economy. On the other hand, an optimal distributor cap is key to maintaining voltage levels. It protects against wear and tear, prolonging the system’s life. When not inspected regularly, these parts can cause serious engine problems.

Another crucial aspect is the ignition coil, which transforms battery voltage into a higher voltage. Research shows that a faulty coil could reduce engine power by up to 20%. In contrast, replacing old coils can boost performance significantly. Many vehicle owners overlook these components, leading to misaligned expectations regarding vehicle efficiency. Regular checks and maintenance of distributor parts can prevent extensive repairs in the future.

Understanding the Functionality of Distributor Parts in Engine Performance

Understanding the functionality of distributor parts is crucial for engine performance. These components manage the ignition process, ensuring efficient fuel combustion. A well-functioning distributor can enhance engine efficiency and power, while a faulty one can lead to misfires or poor performance.

Key parts like the rotor and cap play significant roles. The rotor directs the ignition spark to each cylinder at the right moment. The cap houses the spark plug wires, distributing the electrical charge. Without them, the engine struggles to fire properly. It's interesting to note that even small wear and tear can lead to significant issues.

Maintenance is often overlooked. Many might ignore signs of a failing distributor. Issues like stalling or rough idling can often be traced back to these parts. Regular checks can prevent greater damage. It's essential to understand their importance in the engine system. A small investment in maintenance can save larger repair costs down the line.

Top Popular Types of Distributor Parts and Their Specific Uses

Distributor parts play a crucial role in vehicle performance. Understanding each component is essential for maintenance and repair. Common items include rotors, caps, and wires. Each serves a unique function that directly affects ignition and engine efficiency.

Rotors distribute high voltage to the spark plugs. They wear out over time, often leading to engine misfires. Regular checks can prevent major issues. Caps protect the rotor and allow easy electrical connection. They need to be replaced if you notice corrosion or cracks. Wires carry the electric charge, and fraying or exposure can interfere with ignition.

Often overlooked are the coil and the ignition module. The coil transforms battery voltage into a high-voltage pulse. If it fails, your engine might not start. The ignition module regulates the timing, crucial for effective spark delivery. Unfortunately, these parts can be difficult to diagnose without specialized tools. It’s advisable to consult a professional if problems arise.

Maintenance Tips for Extending the Lifespan of Distributor Parts

Maintaining distributor parts is crucial to ensure optimal performance. Regular inspection helps identify early signs of wear. Check for signs of corrosion or damage. These issues can impact ignition and fuel efficiency. A quick visual inspection can save you from costly repairs later.

Use quality lubricants on moving parts to reduce friction. This practice enhances efficiency and prolongs lifespan. However, avoid over-lubrication, as it can attract dirt. Keep the distributor cap clean too. A dirty cap can misfire, leading to engine troubles. Remember to check wiring for frays or breaks; they can create intermittent issues.

Environmental factors also play a role in wear. Moisture can lead to rust, while dust can cause abrasions. Park your vehicle in a dry place if possible. Even small changes can have significant effects. Regular maintenance might seem tedious, but it pays off in the long run. Be proactive to ensure reliability.

Emerging Technologies in Distributor Part Design and Production

The landscape of distributor part design and production is rapidly evolving. Emerging technologies are reshaping how these components are created and utilized. According to a recent industry report, 52% of manufacturers are investing in additive manufacturing techniques. This shift allows for more complex geometries and lightweight designs that were previously impossible. For instance, 3D printing can reduce material waste by up to 30%, promoting sustainability in production.

Moreover, the integration of IoT devices in distributor parts is on the rise. These smart components can monitor performance in real-time. A survey indicated that 47% of industry professionals believe IoT will become standard within the next five years. However, challenges remain. Not all manufacturers have the expertise to implement these technologies effectively. Training and adaptation processes can be costly and time-consuming, leading to gaps in potential benefits.

Furthermore, the use of advanced materials, such as composites and metals, is gaining traction. These materials offer enhanced durability and performance. Yet, the transition to these new materials may pose compatibility issues. Companies must carefully assess their supply chains and manufacturing processes. Balancing innovation with practicality remains a crucial aspect of evolving distributor part design.

Top 10 Distributor Parts You Need to Know About

Related Posts

-

2025 Top 5 Essential Car Tools Every Vehicle Owner Must Have

-

Discover the Essential Car Pieces Every Vehicle Owner Should Know About

-

Why Quality Car Parts Matter: Your Ultimate Guide to Choosing the Best Parts for Your Vehicle

-

Exploring Key Car Factors: How They Influence Your Vehicle’s Performance and Value

-

How to Choose the Right Steering System for Your Vehicle Instructions Guide

-

Why Engine Parts Matter for Your Vehicle's Performance and Longevity