Top 10 Engine Bearings You Should Know About?

Understanding engine bearings is crucial for anyone interested in automotive mechanics. These components play a vital role in ensuring a smooth operation of the engine. Engine bearings support rotating parts and reduce friction between metal surfaces.

In this exploration, we will highlight the top 10 engine bearings. Each one has its unique qualities and applications. Some are designed for high-performance vehicles, while others focus on durability for daily drivers. Choosing the right engine bearing can greatly impact an engine's lifespan and efficiency.

Engine bearings should not be taken lightly. The decision requires careful consideration. Overlooking details can lead to costly mistakes. It’s essential to understand the specific demands of your engine. This guide will help navigate through your options and make an informed choice.

Top 10 Engine Bearings: Understanding Their Importance in Engine Performance

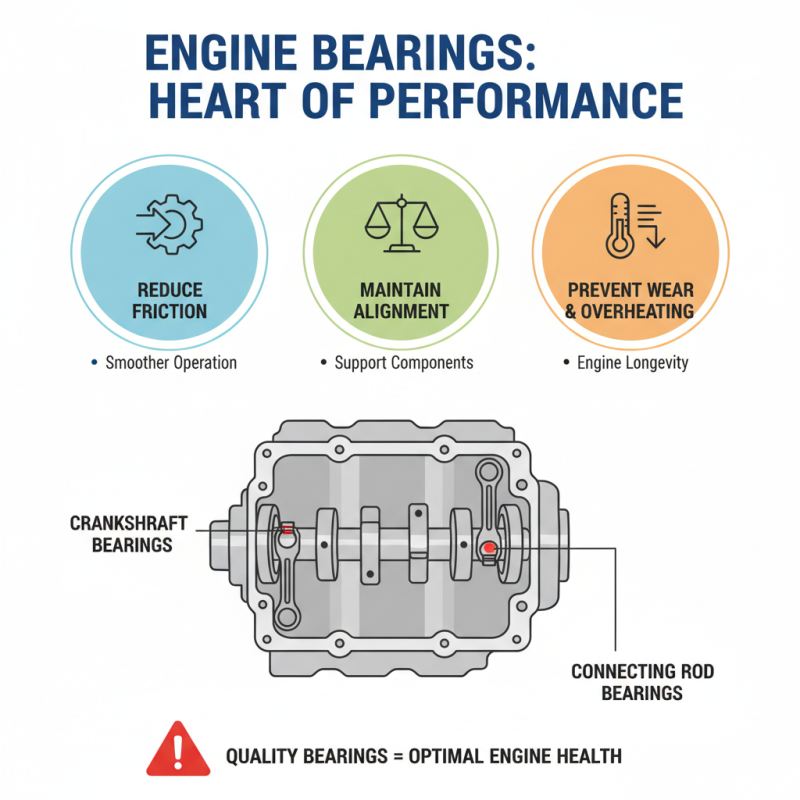

Engine bearings play a crucial role in the performance of an engine. These components reduce friction between moving parts, allowing for smoother operation. They are vital for maintaining proper alignment and supporting crankshafts, connecting rods, and other engine components. Without quality bearings, engines can suffer from premature wear and overheating.

Many don’t realize the impact of worn or damaged bearings. A subtle noise might indicate a problem. Ignoring these signs can lead to catastrophic engine failure. Quality engine bearings can extend the life of your engine significantly. They also contribute to fuel efficiency by reducing energy loss caused by friction. When selecting engine bearings, consider their load capacity and material quality.

Understanding the importance of engine bearings is essential for anyone maintaining a vehicle. Regular inspections can prevent serious issues. It's easy to overlook these parts until it’s too late. Ensuring they are in good condition might seem tedious, but it’s incredibly important. Engine performance is ultimately tied to these often-overlooked components.

Types of Engine Bearings: A Comprehensive Guide to Main, Rod, and Thrust Bearings

Engine bearings play a crucial role in maintaining the functionality of your vehicle's engine. Understanding the main types—main, rod, and thrust bearings—can help you make informed decisions. Each type has unique characteristics and functions, essential for your engine's performance.

Main bearings support the crankshaft and withstand significant loads. They require proper lubrication to prevent wear. Rod bearings connect the crankshaft to the pistons. They face intense pressure during operation. Thrust bearings, on the other hand, manage axial movement, ensuring stable functioning.

**Tips:** Always inspect your bearings regularly for signs of damage. Don't ignore unusual noises—they might indicate a problem. Use high-quality lubricants to extend the life of your bearings. Remember, maintaining proper clearance is essential. Too much or too little can lead to failure. It's not just about replacement; understanding your engine's needs is vital.

Top 10 Engine Bearings Performance Comparison

Material Composition of Engine Bearings: Analyzing Aluminum, Copper, and Bi-Metal Options

The material composition of engine bearings significantly impacts performance and longevity. Engine bearings are critical for reducing friction and wear in an engine. The common materials include aluminum, copper, and bi-metal options. Each material has its unique qualities. For example, aluminum is known for its lightweight nature. It offers good thermal conductivity but can be susceptible to fatigue under high stress.

Copper-based bearings, on the other hand, excel in strength and durability. They provide excellent resistance to corrosion. However, they tend to be heavier. According to industry reports, copper bearings may perform better at higher temperatures, which can be crucial for racing applications. It’s also important to consider the potential for galling during operation—an issue that may arise if the bearing surface is not properly treated.

Bi-metal options combine materials to leverage the strengths of both aluminum and copper. This hybrid approach often results in improved load-bearing capabilities. Yet, not all bi-metal solutions perform equally. Variability in the manufacturing process can lead to inconsistencies, despite the advantages. This raises questions about quality control in the industry. Consequently, choosing the right bearing material requires careful consideration of both the application and the operating conditions.

Key Specifications and Standards: Industry Metrics for Quality and Performance

When choosing engine bearings, understanding key specifications is essential. Measurements like width, diameter, and material type determine their performance. For example, thickness impacts load distribution. A thicker bearing may bear more load, but can also increase friction. Balancing these factors is critical for optimal performance.

Industry standards play a vital role too. Specifications related to clearance, hardness, and surface finish define quality. The right clearance can reduce wear and increase lifespan. However, achieving precise clearance requires careful installation. Many overlook this step, leading to premature failure. It's crucial to ensure that the chosen bearing meets all necessary benchmarks.

Lastly, bear in mind the environmental factors. Things like temperature and lubrication methods affect bearing choice. Operating under high temperatures may demand a different material. Not all standard specifications account for unique operating conditions. Always reflect on these aspects to ensure longevity and performance.

Top 10 Engine Bearings You Should Know About

| Bearing Type | Material | Size Range (mm) | Load Rating (N) | Temperature Resistance (°C) |

|---|---|---|---|---|

| Main Bearing | Copper-lead | 50-100 | 35,000 | 200 |

| Rod Bearing | Aluminum | 40-80 | 30,000 | 220 |

| Thrust Bearing | Bronze | 30-70 | 40,000 | 180 |

| Camshaft Bearing | Babbit | 20-60 | 25,000 | 150 |

| Roller Bearing | Steel | 10-50 | 50,000 | 250 |

| Crankshaft Bearing | Polymer | 20-90 | 55,000 | 200 |

| Spherical Bearing | Composite | 25-75 | 45,000 | 180 |

| Sleeve Bearing | Lead-bronze | 30-100 | 60,000 | 210 |

| Plain Bearing | Tin | 15-50 | 28,000 | 140 |

| Journal Bearing | Copper | 20-70 | 50,000 | 220 |

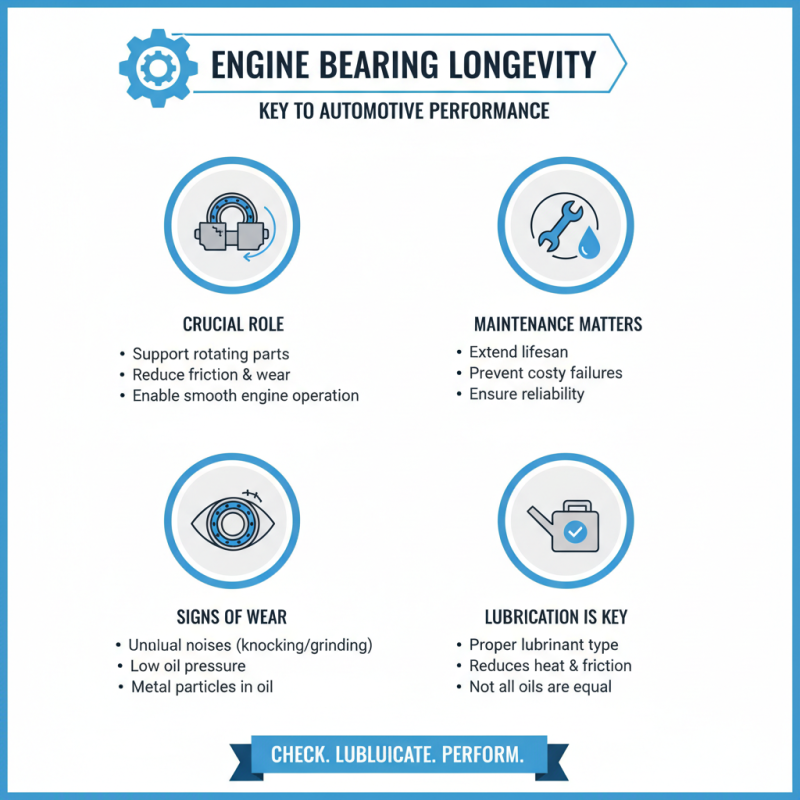

Maintenance Tips for Engine Bearings: Extending Longevity with Best Practices

Engine bearings play a crucial role in automotive performance. Proper maintenance can significantly extend their lifespan. Regularly check for signs of wear and ensure they're properly lubricated. Using the right lubricant type is essential. It reduces friction and heat. Remember, not all lubricants are created equal.

Cleanliness is vital. Dirt can cause damage over time. Always replace oil filters during oil changes. This simple practice keeps contaminants away from bearings. Monitor the engine’s temperature. High temperatures can lead to premature failure. If you notice overheating, investigate the root cause immediately.

Watch for unusual noises coming from the engine. These often indicate issues with the bearings. Don't ignore them. Seek professional help if you’re unsure. Timely intervention is key. However, even with the best practices, wear and tear are inevitable. Understand that perfection is a concept, not a reality. Regular inspections are necessary to address any developing problems early on.

Related Posts

-

Understanding the Importance of Engine Bearings for Enhanced Vehicle Performance

-

How to Choose Engine Bearings for Optimal Performance?

-

How to Identify Different Parts of a Cat for Better Pet Care

-

Top 10 Essential Engine Parts Every Car Owner Should Know About

-

Top 10 Steering Parts You Must Have for Your Vehicle in 2023

-

10 Best Car Distributors to Boost Your Vehicle's Performance in 2023