Top Trends in Car Bearings for Enhanced Vehicle Performance

In recent years, the automotive industry has witnessed significant advancements in technology, particularly in the realm of car bearings. As a crucial component in vehicle performance, car bearings play a vital role in ensuring smooth operation and enhancing overall efficiency. This article delves into the top trends shaping the future of car bearings, highlighting innovative materials, design improvements, and the integration of smart technologies.

From the application of advanced synthetic materials that promise greater durability to the implementation of predictive maintenance systems that monitor the health of bearings in real-time, these trends are not only revolutionizing how car bearings are manufactured but also how they contribute to the overall performance of vehicles. By exploring these developments, we aim to provide insights into how the evolution of car bearings is critical for automotive manufacturers and consumers alike, ultimately leading to more reliable, fuel-efficient, and high-performing vehicles.

Innovative Materials Revolutionizing Car Bearings for Durability

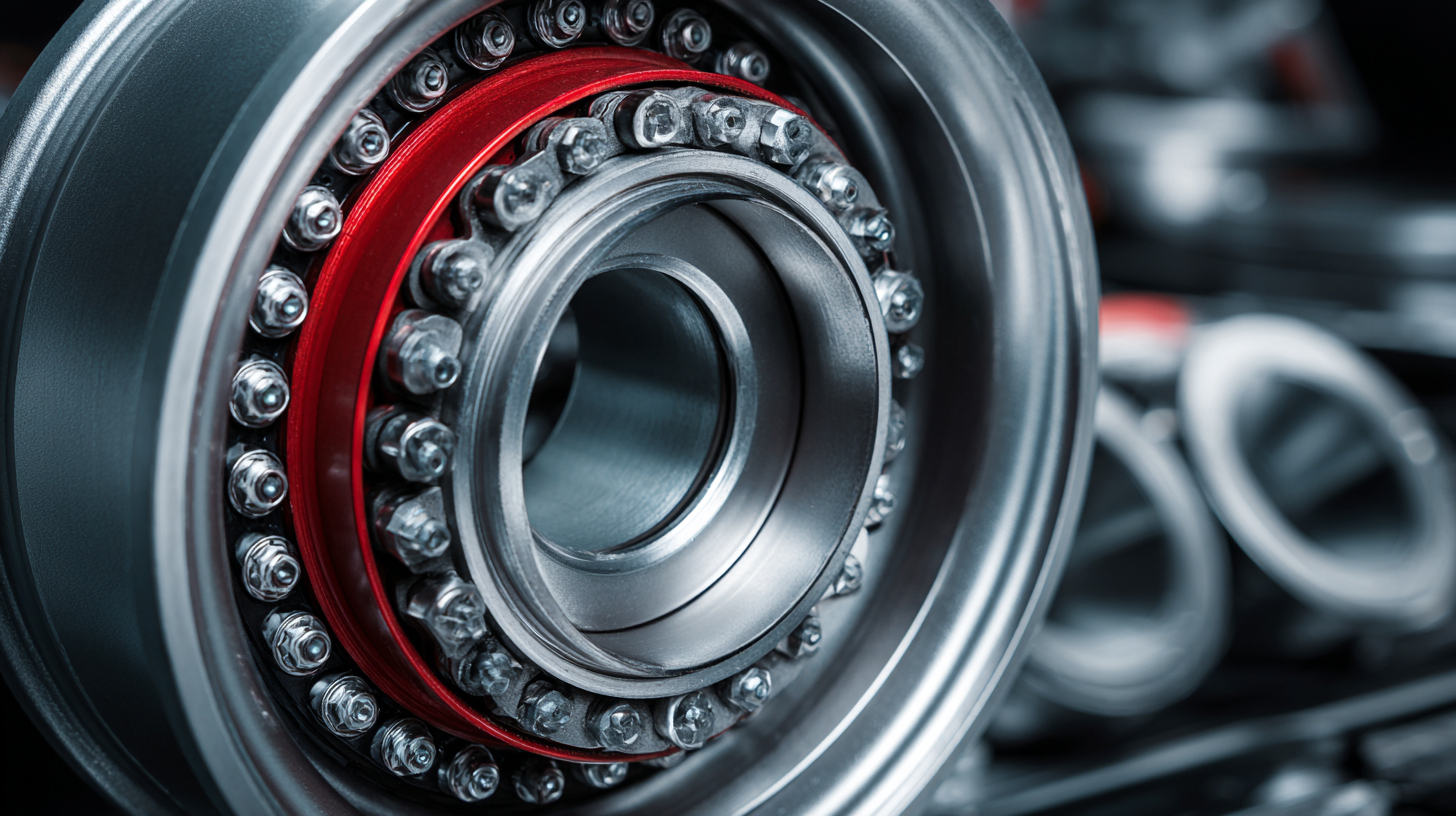

The automotive industry is witnessing significant advancements in the materials used for car bearings, leading to enhanced durability and performance. Innovative materials such as ceramic composites and advanced polymers are being increasingly employed to withstand the harsh conditions that bearings face. These materials not only provide high resistance to wear and tear but also contribute to reducing the overall weight of vehicle components. This shift towards lightweight bearing solutions directly correlates with improved fuel efficiency and better handling characteristics in modern vehicles.

Moreover, the integration of smart materials, which adapt to varying temperatures and loads, is revolutionizing the functionality of car bearings. These materials respond dynamically, ensuring optimal performance under different driving conditions. By minimizing friction through advanced lubrication techniques, these state-of-the-art bearings increase the lifespan of vehicle components and enhance reliability. As manufacturers continue to explore these innovative materials, the future of car bearings promises more efficient, sustainable, and longer-lasting solutions for enhancing vehicle performance.

Advanced Lubrication Techniques for Enhanced Bearing Performance

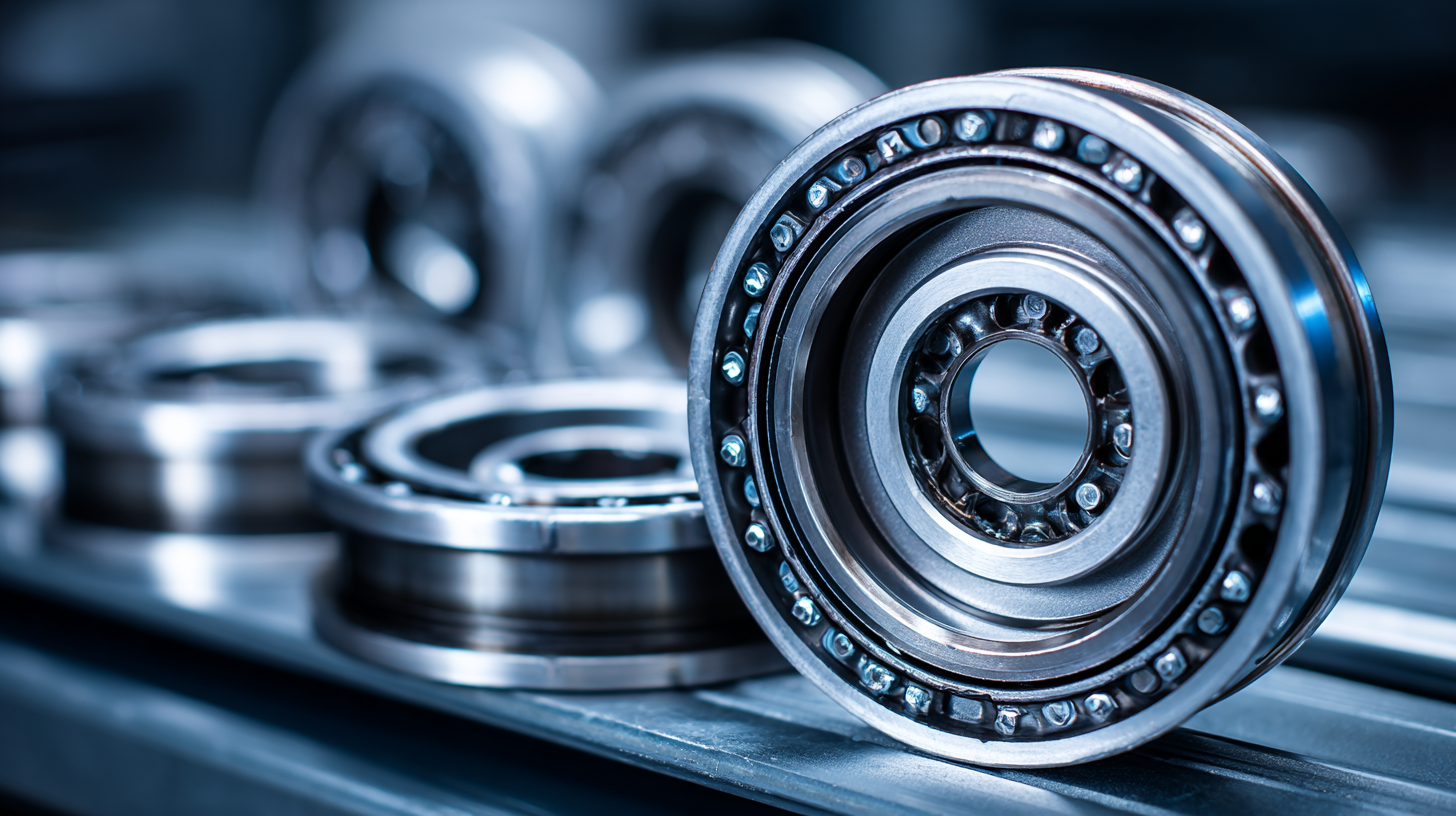

Advanced lubrication techniques play a pivotal role in enhancing the performance of car bearings, which are essential for ensuring smooth operation and longevity in automotive systems.

The emergence of MXene coatings, known for their ultra-low friction and high stress-bearing capacity, showcases the potential of innovative materials in solid lubrication. By grafting benzoic acid diazonium groups onto MXene surfaces, researchers have achieved significant improvements in lubricating properties, making them promising candidates for applications in both passenger vehicles and industrial machinery.

Furthermore, the exploration of non-Newtonian fluids, such as Rabinowitsch fluids, reveals how variations in lubricant properties can enhance the operational efficiency of thrust bearings. These studies indicate that injecting advanced lubrication technologies can mitigate friction and wear, thereby optimizing bearing performance. As the automotive industry continues to embrace cutting-edge materials and techniques, such advances will be crucial in developing bearings that not only perform efficiently but also contribute to the sustainability and reliability of vehicle performance in the long term.

Smart Sensors Enhancing Real-Time Monitoring of Bearing Health

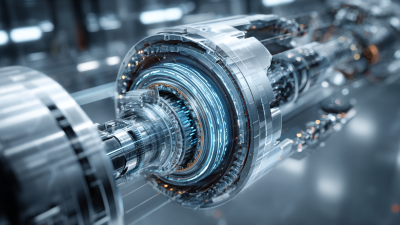

The integration of smart sensors into car bearings marks a significant advancement in vehicle performance and reliability. These sensors provide real-time monitoring of bearing health, allowing for the early detection of anomalies and potential failures. By continuously measuring parameters such as temperature, vibration, and rotational speed, manufacturers can gather valuable data that informs maintenance schedules and enhances overall vehicle safety.

The integration of smart sensors into car bearings marks a significant advancement in vehicle performance and reliability. These sensors provide real-time monitoring of bearing health, allowing for the early detection of anomalies and potential failures. By continuously measuring parameters such as temperature, vibration, and rotational speed, manufacturers can gather valuable data that informs maintenance schedules and enhances overall vehicle safety.

Moreover, smart sensors enhance predictive maintenance strategies by analyzing trends in the collected data. This capability helps in identifying wear patterns and operational stresses that traditional inspection methods might overlook. As a result, automotive engineers can optimize bearing design and material selection, ensuring that vehicles not only perform better but also have longer lifespans. Such innovations in bearing technology are pivotal for the evolution of smart vehicles, contributing to their reliability and efficiency on the road.

The Role of Design Optimization in Improving Bearing Efficiency

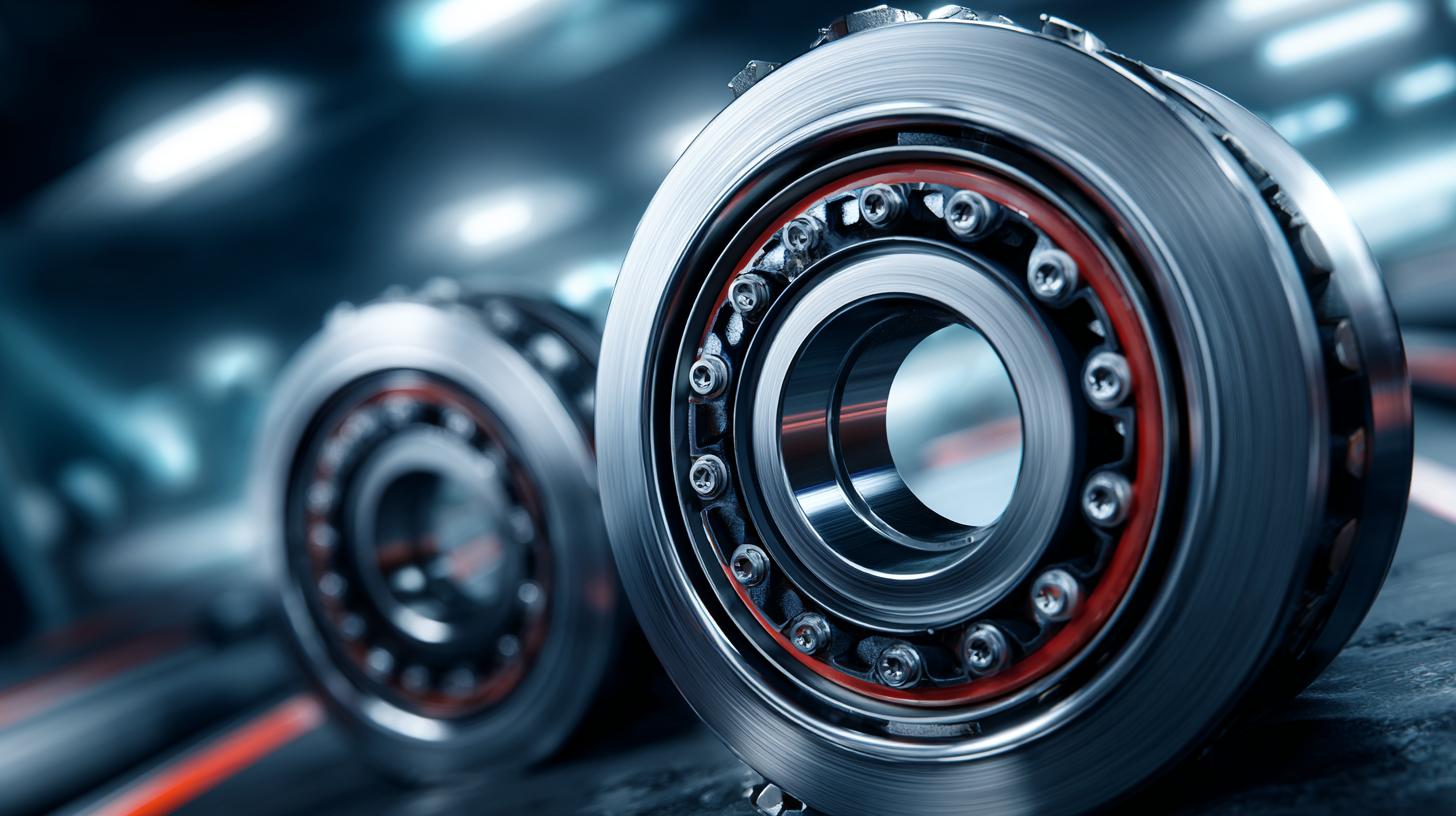

The design optimization of car bearings plays a crucial role in enhancing vehicle performance and overall efficiency. By meticulously refining the geometry of bearings, manufacturers can significantly reduce frictional losses, which directly impacts fuel consumption and longevity. Advanced computer-aided design (CAD) tools allow engineers to simulate various loading conditions, leading to the creation of innovative bearing profiles that can withstand greater stresses while maintaining smooth operational characteristics.

Moreover, utilizing materials with superior properties such as lightweight composites and high-performance alloys contributes to improved bearing performance. These materials not only reduce the weight of the bearing assemblies but also enhance thermal conductivity and corrosion resistance. As a result, optimized bearings contribute to the extended service life of vehicles, minimizing maintenance costs and downtime. In an era where sustainability is paramount, the enhancement of bearing efficiency through design optimization is not just a technical advancement but also a vital step towards achieving greener automotive solutions.

Top Trends in Car Bearings for Enhanced Vehicle Performance

| Trend | Description | Impact on Performance | Design Optimization Techniques |

|---|---|---|---|

| Hybrid Materials | Utilization of composite materials to enhance durability | Increases lifespan and thermal stability | Advanced material selection and finite element analysis |

| Reduced Friction Coatings | Implementation of specialized coatings to minimize friction | Enhances fuel efficiency and overall performance | Surface treatment and micro-texturing techniques |

| Smart Bearings | Integration of sensors for real-time monitoring | Prevents failures through predictive maintenance | IoT technology and data analytics |

| Lightweight Designs | Focus on reducing weight without sacrificing strength | Improves vehicle acceleration and handling | Topology optimization and additive manufacturing |

| Noise and Vibration Reduction | Design features that minimize noise and vibration | Enhances passenger comfort and product quality | Damping materials and optimization of geometries |

Sustainability Trends in Car Bearings for Eco-Friendly Vehicles

Recent trends in the automotive industry highlight a growing emphasis on sustainability, particularly in the development of car bearings. As electric and hybrid vehicles become more prevalent, manufacturers are increasingly focused on eco-friendly materials and processes for producing components such as bearings. A significant shift towards localized production is seen as manufacturers seek to minimize their carbon footprint and enhance supply chain resilience. Reports indicate that the automotive wheel hub bearing aftermarket is expected to increase from USD 1.11 billion in 2023 to USD 1.2 billion by 2025, showcasing the demand for more sustainable products in this sector.

Tips: When selecting bearings for eco-friendly vehicles, consider those made from recycled or bio-based materials. This not only contributes to sustainability but can also improve your vehicle's overall performance.

Moreover, innovative packaging solutions are emerging as part of the drive for eco-friendliness. For instance, firms are exploring fiber-based alternatives to traditional plastics to reduce waste associated with automotive parts. Environmental sustainability in production processes, including the use of smart bearings embedded with IoT technology for efficiency, is fundamental for aligning with green initiatives. The automotive coolant market is also projected to reach USD 11.61 billion by 2034, reflecting a broader industry transition towards greener solutions.

Tips: Look for suppliers who emphasize sustainable production practices and support them by opting for products that adhere to environmental standards. This can lead not only to better performance but also to a positive impact on the planet.

Related Posts

-

The Hidden Role of Car Bearings in Ensuring Smooth and Safe Driving

-

Unlocking the Future: How Emerging Technologies are Revolutionizing the Motor Parts Industry

-

Understanding the Role of Car Distributors: Your Guide to a Smooth Automotive Supply Chain

-

Exploring Innovative Steering Parts for Enhanced Vehicle Performance in 2023

-

Exploring Key Car Factors: How They Influence Your Vehicle’s Performance and Value

-

Ultimate Guide to Choosing the Best Brake Parts for Your Vehicle